Home > Electrodes > AWS Class E309/309H-16 Electrodes

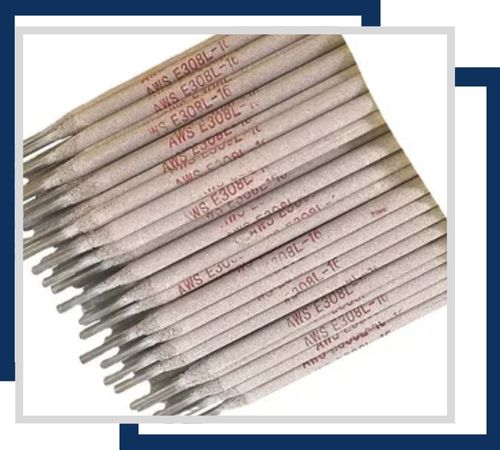

MERIH STAINLESS, based in Istanbul, Turkey, specializes in crafting top-notch stainless steel welding consumables, including the AWS Class E309/309H-16 electrodes. These electrodes are specifically engineered for welding austenitic stainless steels that demand outstanding heat and corrosion resistance, particularly in high-temperature settings. Manufactured with rigorous quality standards, they ensure stable arc performance, minimal spatter, and effortless slag removal. MERIH STAINLESS distributes these electrodes worldwide, catering to industries such as power generation, chemical processing, and shipbuilding, where strong and dependable welds are crucial for safety and efficiency.

The AWS Class E309/309H-16 electrodes boast a chemical makeup of roughly 23–25% Chromium, 12–15% Nickel, and a carbon content of ≤0.04% for E309 and ≤0.08% for E309H. The increased carbon in E309H enhances creep strength, making it suitable for high-temperature tasks. Their mechanical properties include a tensile strength of at least 520 MPa, yield strength of at least 240 MPa, and elongation of at least 30%. With a rutile coating, these electrodes provide smooth arc behavior, easy slag removal, and a great bead appearance, making them perfect for all-position welding while ensuring consistent, high-quality results.

| Classification | AWS A5.4, E309/309H-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E309/309H-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

Designed for welding stainless steel to mild steel or other stainless steel types, these electrodes offer high corrosion resistance. Typically available in sizes like 3/32″ to 1/8″ diameter, they provide excellent weld quality with minimal spatter.

These electrodes are ideal for general-purpose welding, offering good corrosion resistance for stainless steel applications. Sizes usually range from 1/8″ to 3/16″ in diameter, and they ensure smooth welding with light flux coatings for improved visibility and control.

Suitable for heavy-duty welding tasks, these electrodes enhance corrosion resistance and are used for thick stainless steel sections. Common sizes include 5/32″ to 1/4″ diameter, featuring a thicker coating for robust and stable arc performance.

These electrodes are commonly utilized for welding 309 and 309H stainless steels in various applications, including furnace components, heat exchangers, boilers, and chemical processing equipment. Their exceptional resistance to oxidation and corrosion at elevated temperatures makes them ideal for use in petrochemical facilities, power plants, and marine environments. MERIH STAINLESS guarantees that these electrodes comply with international standards, offering welders reliable consumables that produce durable, crack-resistant welds even in the toughest conditions.

The AWS Class E309/309H-16 electrodes primarily are used on dissimilar metal welds particularly in joining other grades of stainless steels as well as where stainless steel may be combined with mild steel. These electrodes, in particular exhibit excellent corrosion properties, high temperatures strength, improved toughness, make them ideal usage in chemical processes, petrochemical, electrical power generation environments, and other marine environments. They are generally used for welding components exposed to heat and corrosive environments, such as heat exchangers, pressure vessels and pipelines.

©2024 Merih Stainless All Rights Reserved.