Home > Electrodes > AWS Class E309/309L-16 Electrodes

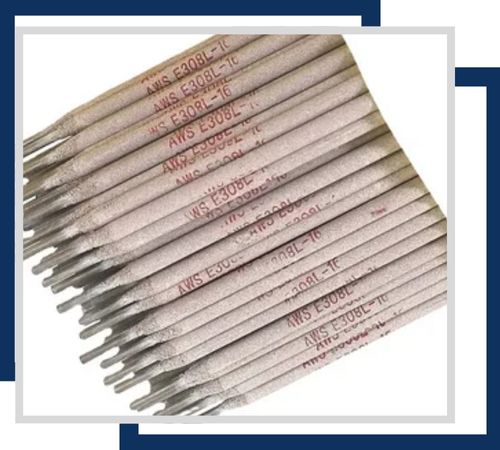

MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer of stainless steel welding consumables, including the AWS Class E309/309L-16 electrodes. These electrodes are specifically designed for welding austenitic stainless steels to carbon steels, making them perfect for joining different types of metals. With a commitment to high-quality standards, MERIH STAINLESS guarantees that these electrodes deliver reliable arc stability, minimal spatter, and easy slag removal. Their products cater to a variety of industries, such as chemical processing, power generation, and shipbuilding, ensuring strong and durable welds even in tough environmental and thermal conditions.

The AWS Class E309/309L-16 electrodes boast a composition of about 23–25% Chromium, 12–14% Nickel, and a low carbon content (≤0.04% for 309L), which provides outstanding resistance to oxidation and corrosion, particularly in high-temperature settings. These electrodes typically achieve a tensile strength of ≥520 MPa, yield strength of ≥240 MPa, and elongation of ≥30%. Their rutile coating ensures smooth arc performance and a pleasing weld bead appearance, along with excellent slag detachability. The low carbon 309L variant helps minimize carbide precipitation, which prevents intergranular corrosion in the welded areas, ensuring top-notch weld quality.

| Classification | AWS A5.4, E309/309L-16 |

| Form | Welding Electrode, Welding Rods |

| Type Of Current | AC-DCEP (Direct Current Electrode Positive) |

| Welding Position | F, V, OH, H |

| Size | 2.0 mm, 2.50 mm, 3.15 mm, 4.00 mm, 5.0 mm |

| AC/DC+ | AC or DC (+) |

| JIS Specification | BS 2926 19.9 A R |

| Other Specification | DIN 8556 E19 9 R 23 A |

| AWS E309/309L-16 Coated Electrodes Application & uses |

|

| C | Cr | Ni | Mo | Mn | Si | P | S | Cu |

| 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.5-2.5 | 1.00 | 0.04 | 0.03 | 0.75 |

Contact us to get a quick quote for your requirement.

These electrodes offer good resistance to oxidation and corrosion in moderate environments. Typically available in sizes ranging from 1/16″ to 1/8″ in diameter, they are ideal for applications requiring light coatings and smooth welding.

Designed for enhanced corrosion resistance and durability, these electrodes are available in diameters from 3/32″ to 5/32″. The heavy coating ensures a robust weld in demanding conditions, providing stronger welds with superior mechanical properties.

Offering excellent corrosion resistance, these electrodes are used in shielded metal arc welding applications. They are available in diameters such as 1/16″, 3/32″, and 1/8″, providing versatile options for various welding needs.

We take great care in securely packing and shipping our AWS Class E309/309L-16 Electrodes, using wooden boxes with waterproof material and lifting points for easy transport. Along with each order, we provide essential documents, including a commercial invoice, packing list, heat treatment chart and material testing certificates. Our comprehensive documentation ensures full transparency and guarantees client satisfaction.

These electrodes are commonly used for welding stainless steels like 309 and 309L, as well as for connecting stainless steel to carbon or low-alloy steels in various applications, including chemical plants, boilers, heat exchangers, and structural components. They are especially well-suited for environments that experience high temperatures and corrosive conditions. MERIH STAINLESS distributes these electrodes worldwide, providing welders with reliable consumables for creating high-strength, corrosion-resistant welds that meet rigorous industry standards and can endure challenging service conditions.

©2024 Merih Stainless All Rights Reserved.