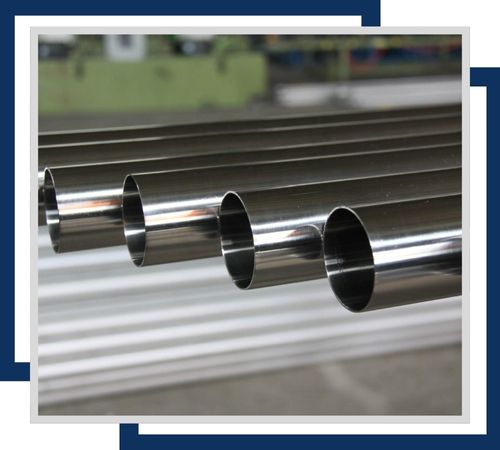

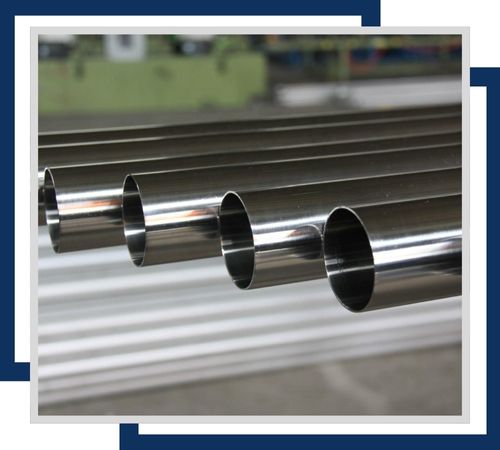

MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of high-quality SMO 254 Pipes. Known for their remarkable resistance to corrosion and outstanding mechanical properties, these pipes are designed to meet the tough demands of today’s industries. MERIH STAINLESS prides itself on precision manufacturing, rigorous quality control, and prompt delivery, making their SMO 254 Pipes a dependable choice for critical applications. Trusted across various sectors that require high-performance stainless steel solutions, the company blends technical know-how with state-of-the-art production methods, serving clients who value durability, strength, and long-lasting reliability in their piping systems.

| Specifications | : | ASTM A 409 ASME SA 409 / ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 |

| Dimensions | : | ASTM, ASME and API |

| Size | : | 3/4″ – 12″ |

| Specialized in | : | Large Diameter Size |

| Thickness | : | 20 Swg., 18 Swg., 16 Swg., 14 Swg., 12 Swg., 10 Swg., & Sch. 10, Sch. 40, Sch. 80 etc. |

| Type | : | Seamless / ERW / Welded / Fabricated |

| Form | : | Round, Hydraulic Etc |

| Length | : | Single Random, Double Random & Cut Length. |

| End | : | Plain End, Beveled End, Treade |

| SMO 254 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20. |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 |

Contact us to get a quick quote for your requirement.

SMO 254 Pipes are made from a high-alloy austenitic stainless steel, primarily featuring chromium (20–22%), nickel (18–20%), and molybdenum (6–7%), along with trace amounts of nitrogen and manganese. This special blend gives them excellent resistance to pitting, crevice corrosion, and chloride stress corrosion cracking. On the mechanical side, SMO 254 Pipes showcase impressive tensile strength, yield strength, and exceptional toughness, ensuring they maintain their structural integrity even in extreme temperatures and harsh environments. This combination of elements guarantees long-lasting performance, making these pipes perfect for demanding industrial applications that require both strength and corrosion resistance.

The F44 seamless pipe is a high-strength, corrosion-resistant pipe made from alloy steel, often used in demanding environments like chemical processing, petrochemical, and power generation due to its durability.

UNS S31254 welded pipe is a high-quality, corrosion-resistant stainless steel pipe, ideal for harsh environments. It offers excellent resistance to pitting and crevice corrosion, commonly used in chemical and marine applications.

SMO 254 round pipe is a high-alloy stainless steel pipe known for its exceptional resistance to corrosion and pitting. It’s used in challenging environments, such as chemical processing and marine applications.

ASTM A409 254 SMO seamless pipes are high-grade, corrosion-resistant pipes designed for severe environments. They offer superior strength and durability, making them ideal for chemical processing and marine applications.

SMO UNS S31254 round pipe is a high-performance stainless steel pipe known for exceptional resistance to corrosion and pitting. Ideal for harsh environments, it’s widely used in chemical and marine industries.

F44 254 SMO welded pipes are high-strength, corrosion-resistant pipes used in demanding applications. They offer excellent resistance to pitting and crevice corrosion, making them suitable for chemical and marine environments.

Merih Stainless is a leading supplier, and stockist of high-quality SMO 254 Pipes in Istanbul, Turkey. Our products are widely used in various applications, and we are committed to delivering excellent service, resulting in high customer satisfaction. Our unique finishing techniques further distinguish us in the stainless steel industry. We are dedicated to consistently providing superior products and effectively meeting our customer’s needs.

SMO 254 Pipes find extensive use in industries that demand high corrosion resistance and structural durability. They are particularly well-suited for chemical processing plants, desalination systems, oil and gas refineries, and marine environments, thanks to their ability to endure harsh chemical and saline conditions. Additionally, they are utilized in heat exchangers, seawater cooling systems, and pollution control equipment. Their blend of strength, toughness, and resistance to stress corrosion cracking makes them ideal for high-pressure and high-temperature applications. SMO 254 Pipes deliver reliable, long-term performance in critical infrastructure projects.

©2024 Merih Stainless All Rights Reserved.