MERIH STAINLESS, located in Istanbul, Turkey, has built a solid reputation as a reliable manufacturer and supplier of top-notch Stainless Steel 201 Coils. These coils are known for their durability, corrosion resistance, and versatility, making them perfect for a wide range of industrial uses. With impressive mechanical strength, toughness, and oxidation resistance, these coils are crafted using cutting-edge manufacturing techniques and rigorous quality control measures. MERIH STAINLESS caters to various sectors, including construction, automotive, chemical processing, marine, and food processing, ensuring that every coil adheres to international standards. Their commitment to customization, precision, and timely delivery has positioned them as a trusted global supplier of stainless steel coil products.

Stainless Steel 201 Coils are made from a blend of chromium, manganese, and nickel, typically featuring 16–18% chromium, 3.5–5.5% nickel, and 5.5–7.5% manganese. This unique composition grants them excellent corrosion resistance, high tensile strength, and remarkable ductility. On the mechanical side, 201 coils boast impressive yield and tensile strength, toughness, and resistance to deformation, making them ideal for forming, fabrication, and industrial applications that demand both strength and durability.

| Item | SS Coil(Hot rolled, cold rolled) |

| Inner Diameter | 610 +0/-5 mm |

| Width | 610~2000 mm |

| Thickness | 2.5~10.0 mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Material | SS 202 Coils, SS 304 Coils, SS 316 Coils, SS 321 Coils, SS 310 Coils , SS 410 Coils, SS 420 Coils, SS 416 Coils |

| Surface | 2D, etching, 8K, 2B, BA, NO.4, hair line,NO.1, NO.8, Brush, checkered, mirror,embossed, sand blast etc |

| Standard | ASTM A240, ASTM A167, JIS4304-2005, GB/T3280-2007, EN10088-2-2005, etc |

| origin | Indian Origin, European Origin, Japanese Origin, US Origin, Korea Origin, Thailand Origin, Taiwan Origin |

| Element | C | Si | Mn | Cr | N | P | S | Ni |

| Content | ≤0.15 | ≤0.75 | ≤5.5-7.5 | 16.0-18.0 | ≤0.25 | ≤0.060 | ≤0.03 | 3.5-5.5 |

| C | Mn | P | S | Si | Cr | Ni | N | Fe | |

|---|---|---|---|---|---|---|---|---|---|

| MIN | – | 5.50 | – | – | – | 16.0 | 3.5 | – | – |

| MAX | 0.15 | 7.50 | 0.060 | 0.030 | 1.00 | 18.0 | 5.5 | 0.25 | BAL |

Contact us to get a quick quote for your requirement.

The Slitting Coils under SS 201 contain grade 201, stainless steel characterized for corrosion resistance. They are preferably used in production, construction and other industrial work.

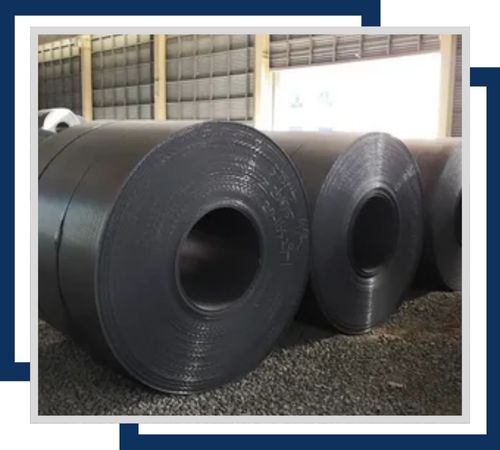

SS 201 hot-rolled coils. The product obtained by processing SS at high temperature provides strength. They are utilized in construction work and industries; they resist abrasive and corrosive erosion.

SS 201 cold rolled coils are stainless steel coils processed at room temperature, thus giving a bright finish and precise dimensions. They are ideal for applications requiring a high-quality surface and strength.

201 stainless steel chequered coils have a textured surface for better grip and durability. These are perfect for flooring and structural applications, where strength is combined with aesthetic appeal in various industrial uses.

Stainless Steel 201 UNS S31635 coils are high-performance stainless steel products that offer excellent corrosion resistance and strength. They are suitable for demanding applications and provide durability and reliability in various industrial environments.

201 stainless steel golden laser pattern coils have the eye-catching laser pattern with an attractive gold finishing. They present aesthetic appeal together with durability suitable for decorative and architectural application.

These Stainless Steel 201 Coils find their place in industries that require robust, dependable, and corrosion-resistant materials. They are perfect for construction frameworks, automotive parts, chemical processing equipment, marine applications, and food processing machinery. Moreover, they are utilized in architectural projects, industrial machinery, and HVAC systems where long-lasting performance and wear resistance are crucial. Offered in a variety of thicknesses, widths, and finishes, 201 coils provide engineers and manufacturers with a versatile, high-performance solution for a broad spectrum of industrial and commercial needs.

Stainless Steel 201 Coils find extensive uses where strength coupled with aesthetic appearance are required. Major applications include: car trim panels; architectural building sheets; domestic and commercial kitchens’ equipment as well as an indoor decoration tool, appliances structural parts, and industrial structural part. As this material oxidizes less with fewer maintenance requirements it will be widely suitable for in house and general weather conditions used under moderate exposures which balance a level of service quality with budget constraints for various projects.

©2024 Merih Stainless All Rights Reserved.