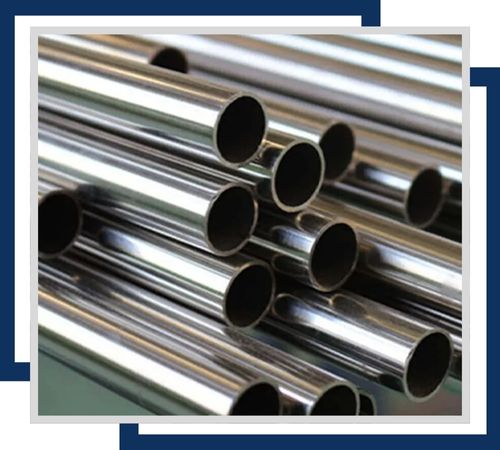

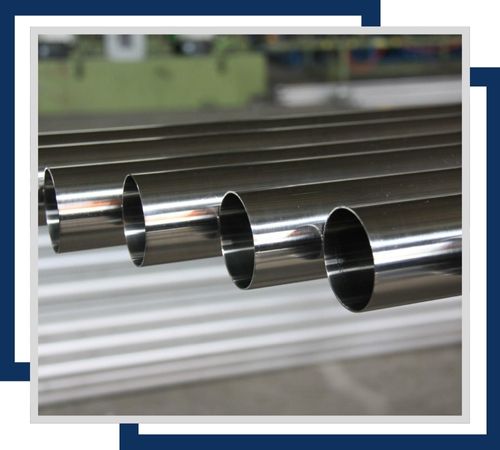

MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top-notch manufacturer and supplier of high-quality Stainless Steel 201 Pipes. These pipes are designed to be durable and resistant to corrosion, making them perfect for a variety of industrial uses. Renowned for their impressive strength, toughness, and ability to resist oxidation and wear, these pipes are crafted using cutting-edge production techniques and rigorous quality control measures. MERIH STAINLESS caters to a range of industries, including construction, automotive, chemical processing, marine, and food processing, ensuring that every pipe adheres to international standards. With a commitment to customization, precision, and timely delivery, the company has built a reputation as a reliable global supplier of stainless steel piping solutions.

Stainless Steel 201 Pipes are created from an austenitic chromium-manganese-nickel stainless steel alloy, which typically includes 16–18% chromium, 3.5–5.5% nickel, and 5.5–7.5% manganese. This specific blend offers excellent corrosion resistance, high tensile strength, and remarkable durability in moderate industrial settings. In terms of mechanics, 201 pipes showcase high yield and tensile strength, toughness, and resistance to deformation under stress, making them ideal for applications that demand both structural integrity and wear resistance.

| Standard Specification | 201 Stainless Steel Pipe |

| Surface Finish | Cold Finish, Polished, Annealing, Bright, Pickling |

| Schedule Pipe Thickness Range | SCH10, SCH XXS, SCH 40, SCH 160, SCH 80S, SCH 5, SCH 80, SCH XS Supplier in Mumbai |

| Types | ERW, Welded, Seamless, EFW |

| Sizes | ½ to 6 Inch |

| Manufacturing Technology | Hot / Cold Formed |

| Technique | Cold Rolled Hot Rolled |

| Wall Thickness | 0.1 To 60 mm |

| Manufacturing Shapes | Square, Round, Rectangle, Box Section |

| Standard | ASTM, GOST, ASME, DIN, EN, JIS, AMS, AISI, GB |

| Element | Content |

|---|---|

| Iron | 72 |

| Carbon | 0.15 |

| Chromium | 16.0 – 18.0 |

| Silicon | 1.0 |

| Manganese | 5.50 – 7.50 |

| Nickel | 3.50 – 5.50 |

| Nitrogen | 0.25 |

| Type | Tensile Strength | Yield Strength | Hardness Rockwell | Elongation |

|---|---|---|---|---|

| SS 201 ¾ Hard | 175 | 135 | 37 – 41 HRC (typical) | 12.0 |

| SS 201 ¼ Hard | 125 | 75 | 25 – 32 HRC (typical) | 25.0 |

| SS 201 Ann | 75 | 38 | HRB 95 max. | 40% |

| SS 201 ½ Hard | 150 | 110 | 32 – 37 HRC (typical) | 18.0 |

| SS 201 Full Hard | 185 | 145 | 41 – 46 HRC (typical) | 9.0 |

Contact us to get a quick quote for your requirement.

We offers premium Stainless Steel 201 Pipes with tests for durability and performance. Every pipe is tested at each stage- mechanical and chemical analysis-to adhere to international standards. Certifications ensure the strength, corrosion resistance, and reliability of the pipes, making them perfect for various industrial applications requiring superior material performance.

Stainless Steel 201 Seamless Pipe is a high-temperature alloy with excellent oxidation resistance, offering superior strength and durability in harsh environments. Ideal for aerospace and industrial applications

Stainless Steel 201 Welded Pipe provides excellent oxidation and corrosion resistance, suitable for high-temperature applications. Its welded construction offers cost efficiency and structural integrity in various industrial and aerospace uses.

Stainless Steel 201 ERW Pipe combines high-temperature resistance with exceptional durability. Its Electric Resistance Welded (ERW) construction ensures reliable performance in demanding environments, ideal for industrial and high-heat applications.

Stainless Steel TP 201 Seamless Pipes offer superior heat resistance and corrosion protection, ideal for high-temperature applications. Their seamless design ensures durability and reliability in industrial and aerospace environments.

Stainless Steel 201 Round Pipe features excellent heat resistance and corrosion resistance. Its round shape ensures versatility and strength, making it suitable for high-temperature industrial applications and structural uses.

Stainless Steel 201 EFW Pipe provides robust heat and corrosion resistance with Electric Fusion Welded construction. Ideal for high-temperature and industrial applications, it ensures durability and structural integrity.

These Stainless Steel 201 Pipes are extensively utilized in industries that need dependable, cost-effective, and corrosion-resistant piping solutions. They are perfect for water pipelines, chemical processing systems, food and beverage equipment, architectural frameworks, and automotive applications. Moreover, they find their place in marine structures, industrial machinery, and construction projects where strength and long-lasting performance are essential. Available in a variety of sizes, thicknesses, and finishes, 201 pipes offer engineers and designers a versatile and high-performance option for a wide range of industrial and commercial applications.

©2024 Merih Stainless All Rights Reserved.