MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top-notch manufacturer and supplier of high-quality Stainless Steel 201 Tubing. This tubing is designed to be durable and resistant to corrosion, making it perfect for a variety of industrial uses. Renowned for its impressive strength, toughness, and ability to resist oxidation and wear, this product is crafted using cutting-edge production techniques and rigorous quality control measures. MERIH STAINLESS caters to a range of industries, including construction, automotive, chemical processing, marine, and food processing, ensuring that every tube adheres to international standards. With a commitment to precision, customization, and prompt delivery, the company has built a solid reputation as a trustworthy global supplier of stainless steel tubing solutions.

Stainless Steel 201 Tubing is created from an austenitic chromium-manganese-nickel stainless steel alloy, which typically includes 16–18% chromium, 3.5–5.5% nickel, and 5.5–7.5% manganese. This unique blend offers excellent corrosion resistance, high tensile strength, and remarkable ductility. In terms of mechanical properties, 201 tubing boasts high yield and tensile strength, toughness, and resistance to deformation, making it ideal for forming, fabrication, and structural applications that demand both durability and strength.

| Standard | ASTM, AISI, GB, JIS, customers’ requests available |

| Size | Round Tube: OD: 16-119mm or customized |

| Thickness | 0.25mm-3.0mm |

| Length | 6m or according to customers’ request |

| Sample | Free sample is available, but freight should be paid by you |

| Tolerance | Outer diameter: ±0.2mm |

| Thickness: ±0.05mm | |

| Length: ±0.5mm | |

| Ends | In plain end or bevelled ends or as your requirements |

| Welding Line Type | ERW (Electrical Resistance Weld) |

| Finishing | A. Sanded |

| B. Gloss #400,Mirror #600 – #1000 | |

| C. Brushed | |

| D. Wood Grain | |

| E. Embossed, Threaded | |

| Application | Decorations, constructions, food industry, etc. |

| Certification | ISO, SGS |

| Round Pipe Size | 16, 17, 18, 19, 20, 21, 22, 23, 25, 28, 31.8, 35, 36, 38.1, 48, 50.8, 60, 63.5, 76.2, 89, 101, 114 mm |

| Square Pipe Size | 17, 18, 19, 20, 21, 22, 23, 24, 25, 28, 30, 36, 38, 50 mm |

| Rectangle Pipe Size | 10*30, 10*40, 10*50, 20*10, 23*11, 24*12, 25*13, 28*25, 28*13, 29*14, 30*15, 30*20, 30*22, 34*22, 36*23, 50*25, 60*30, 75*45, 95*45 mm |

| Thickness | exact 0.25, 0.28, 0.32, 0.37, 0.41, 0.51, 0.61, 0.71, 0.91, 1.11, 1.15, 1.41 mm |

| Length | 6m or according to customer’s request |

| Outer diameter | 6.35-219mm |

| Tolerance | Outer diameter :±0.2mm |

| Thickness :±0.02mm | |

| Length :±0.5mm | |

| Process method | Code drawn, annealed with nitrogen protection, ultrasonic, automatic shape, polished |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine Sand-blasting machine, etc |

| Origin | West Europe / Japanese / Indian / USA / Korean / American / European |

| Test Certificates | Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report |

| Element | Content (%) |

|---|---|

| Iron, Fe | 72 |

| Chromium, Cr | 16.0 – 18.0 |

| Manganese, Mn | 5.50 – 7.50 |

| Nickel, Ni | 3.50 – 5.50 |

| Silicon, Si | 1.0 |

| Nitrogen, N | 0.25 |

| Carbon, C | 0.15 |

| Type | Yield Strength 0.2% offset (KSI) | Tensile Strength (KSI) | % Elongation (2″ Gauge length) | Hardness Rockwell |

|---|---|---|---|---|

| SS 201 Ann | 38 min. | 75 min. | 40% min. | HRB 95 max. |

| SS 201 ¼ Hard | 75 min. | 125 min. | 25.0 min. | 25 – 32 HRC (typical) |

| SS 201 ½ Hard | 110 min. | 150 min. | 18.0 min. | 32 – 37 HRC (typical) |

| SS 201 ¾ Hard | 135 min. | 175 min. | 12.0 min. | 37 – 41 HRC (typical) |

| SS 201 Full Hard | 145 min. | 185 min. | 9.0 min. | 41 – 46 HRC (typical) |

Contact us to get a quick quote for your requirement.

We provides stainless steel 201 tubing with proper quality assurance by way of strict testing and certification. Every product undergoes thorough inspections in tensile, hardness, and corrosion resistance tests that are all international standards like ASTM and ISO. Being certified for reliability and performance, these tubes ensure durability, safety, and compliance for different industrial and commercial applications.

Stainless Steel 201 Seamless Tubing is available in sizes ranging from 1/8″ to 14″ OD. It is known for its excellent corrosion resistance and high mechanical strength. Ideal for high-pressure applications, it ensures a smooth, uninterrupted flow.

Stainless Steel 201 Welded Tubing comes in sizes from 1/8″ to 24″ OD. It offers good corrosion resistance and weldability. Suitable for structural applications and fluid transportation, it is cost-effective compared to seamless tubing.

Stainless Steel 201 Heat Exchanger Tubes are available in sizes from 1/8″ to 2″ OD. These tubes exhibit superior corrosion resistance and thermal conductivity. They are essential in applications requiring efficient heat transfer.

Stainless Steel 201 Instrumentation Tubing is available in sizes from 1/8″ to 1″ OD. It provides excellent corrosion resistance and precise dimensions. Used in control and measurement devices, it ensures accurate performance.

Stainless Steel 201 Boiler Tubes come in sizes from 1/2″ to 5″ OD. They offer high corrosion resistance and strength under high temperatures and pressures. These tubes are crucial for efficient boiler operations in various industries

Stainless Steel 201 U-Tubes are available in sizes from 1/4″ to 2″ OD. They exhibit excellent corrosion resistance and are formed in a U-shape for heat exchanger applications. Ideal for compact design requirements in heat transfer systems.

Stainless Steel 201 Condenser Tubes are available in sizes from 1/4″ to 1″ OD. These tubes provide superior corrosion resistance and thermal efficiency. Used in condensers to effectively transfer heat and condense vapors.

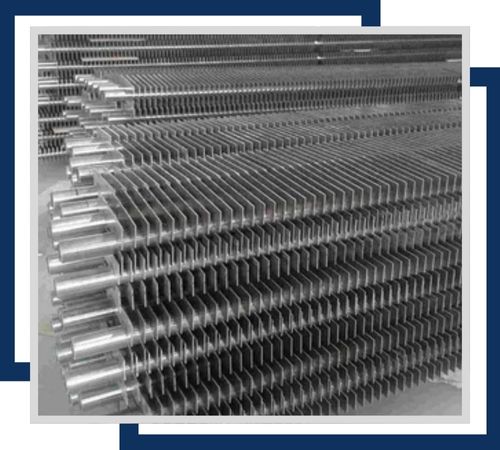

Stainless Steel 201 Fin Tubes come in sizes from 1/2″ to 3″ OD with varying fin heights. They offer excellent corrosion resistance and enhanced heat transfer surface area. Ideal for applications needing improved thermal efficiency

This type of tubing is widely utilized in industries that need reliable, cost-effective, and corrosion-resistant solutions. It’s perfect for construction frameworks, automotive parts, chemical processing systems, marine applications, and food and beverage equipment. Moreover, it finds its place in industrial machinery, architectural projects, and HVAC systems where long-lasting performance is crucial. Available in a variety of sizes, wall thicknesses, and finishes, 201 tubing offers engineers and designers a versatile, high-performance option for a wide range of industrial and commercial needs.

©2024 Merih Stainless All Rights Reserved.