MERIH STAINLESS, located in Istanbul, Turkey, stands out as a leading manufacturer and supplier of top-notch Stainless Steel 253Ma Bars. Known for their precision engineering and commitment to international standards, MERIH STAINLESS consistently delivers products that meet the rigorous demands of various industries. By blending cutting-edge manufacturing technology with strict quality control, they ensure that their products are durable, resistant to corrosion, and built to last. Their 253Ma bars are particularly celebrated for their outstanding performance in high-temperature and harsh environments. With a strong focus on customer satisfaction, MERIH STAINLESS offers customized solutions across different sectors, solidifying their reputation as a reliable partner in the global stainless steel supply chain.

Stainless Steel 253Ma Bars are primarily made up of chromium (22%), nickel (14%), and molybdenum (4%), along with trace amounts of nitrogen and iron, which together provide exceptional corrosion resistance. This alloy boasts impressive mechanical properties, including high tensile strength, remarkable creep resistance, and durability at elevated temperatures reaching up to 1,050°C. Its low thermal expansion and resistance to oxidation make it perfect for high-temperature applications. Additionally, the material shows good toughness and formability, allowing it to maintain its structural integrity even under thermal cycling and mechanical stress, making it a dependable choice for industrial and engineering uses.

| Specifications | ASTM A276 / ASME SA276 & ASTM A479 / ASME SA276 |

| Range | 3.17 MM TO 350 MM DIA |

| Dia Meter | 25mm to 152mm |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging etc |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Grade | C | Mn | Si | S | P | Ni | Cr | Fe | Ce | N |

| 253 MA | 0.05 – 0.1 | 0.8 max | 2.0 max | 2.0 max | 0.04 max | 10.0 – 12.0 | 20.0 – 22.0 | Bal | 0.03 – 0.08 | 0.14 – 0.20 |

| Element | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 253 MA | 7.8 g/cm3 | 600 MPa | 310 MPa | 40 % |

Contact us to get a quick quote for your requirement.

We ensures the highest quality standards for Stainless Steel 253MA Bars through rigorous testing and certification. Each batch undergoes comprehensive tests, including mechanical, chemical, and dimensional assessments. Certified by leading industry bodies, their products meet global quality norms, ensuring reliability, performance, and compliance with international specifications.

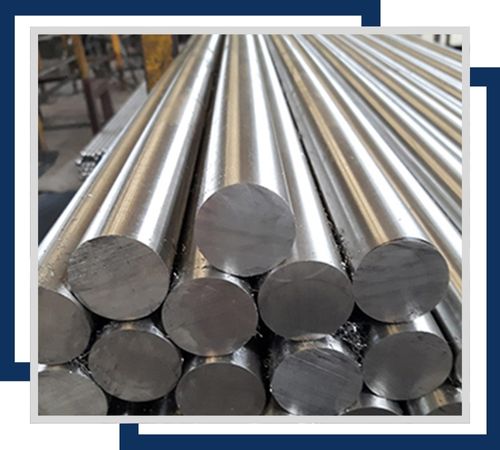

253Ma round bars provide exceptional high-temperature strength and oxidation resistance, ideal for use in furnace components, petrochemical industries, and high-temperature applications requiring durability and performance.

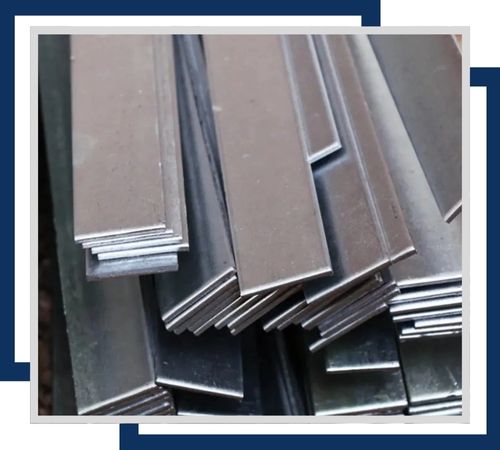

253Ma flat bars are designed for high-temperature and corrosive environments, used in furnace components and petrochemical industries, offering superior strength, oxidation resistance, and long-lasting performance.

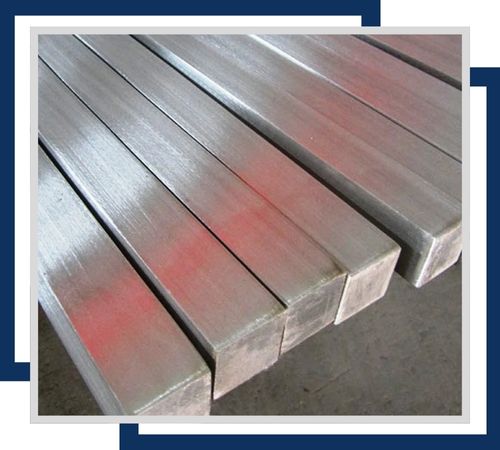

253Ma square bars are suitable for high-temperature applications, providing excellent strength and resistance to oxidation, making them ideal for use in industrial equipment and high-stress environments.

253Ma rectangular bars offer high-temperature strength and oxidation resistance, used in furnace components and industrial applications, ensuring durability and performance in extreme environments.

253Ma hexagonal bars deliver outstanding strength and oxidation resistance at high temperatures, perfect for use in industrial machinery, furnace components, and applications requiring durability in harsh conditions.

253Ma T-bars provide excellent performance in high-temperature environments, used for structural support and components in industrial applications, offering superior strength, oxidation resistance, and reliability.

Stainless Steel 253Ma Bars find extensive application in industries that demand high-temperature strength and corrosion resistance. They play a crucial role in power plants, where they are used for boiler tubes, superheaters, and heat exchangers. In the chemical and petrochemical industries, these bars are utilized in reactor vessels, piping systems, and other process equipment that face aggressive conditions. The alloy is also well-suited for aerospace, automotive, and marine applications, where durability under thermal stress is essential. Furthermore, it is employed in industrial furnaces, kiln components, and other high-temperature manufacturing equipment, ensuring reliability and performance in challenging environments.

©2024 Merih Stainless All Rights Reserved.