MERIH STAINLESS, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of Stainless Steel 304 Tubing, delivering high-quality solutions designed for a variety of industrial and commercial applications. Renowned for its impressive corrosion resistance, durability, and ease of fabrication, Stainless Steel 304 Tubing is crafted under strict quality controls to comply with international standards. It’s widely distributed across sectors like chemical processing, food and beverage, marine, and construction, with MERIH STAINLESS committed to providing reliable products, prompt deliveries, and tailored solutions, making it a trusted partner for stainless steel tubing needs around the globe.

Stainless Steel 304 Tubing consists of 18–20% chromium and 8–10.5% nickel, which together offer remarkable resistance to corrosion, oxidation, and heat. This alloy is not only easy to weld and shape but also suitable for a broad range of fabrication processes. On the mechanical side, 304 tubing boasts high tensile and yield strength, along with excellent toughness and durability, even in cryogenic conditions. Its non-magnetic property when annealed and its ability to withstand various atmospheric conditions make it one of the most versatile grades of stainless steel.

Tube Range : 1/2″ OD – 12″ OD, Guage: 25 SWG – 10 SWG

Outer Diameter : 3.00 mm – 219.10 mm

Wall Thickness : 0.40 mm – 12.70 mm

Schedules : 5, 10S, 10, 30, 40S, 40, 80, 80S, XS, 160, XXH

Length : Upto 30 meters, Custom Cut Lengths

Specifications : ASTM A213 / ASTM SA213

Types : Round, Square, Rectangle, Coil, “U” Shape, Hydraulic & Honed Tubes

| SS | 304 |

|---|---|

| Ni | 8 – 11 |

| Fe | Balance |

| Cr | 18 – 20 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.040 max |

| S | 0.030 max |

| N | – |

| Grade | 304 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

Contact us to get a quick quote for your requirement.

We ensures high quality standards in the processing of Stainless Steel 304 Tubing through a rigorous testing and certification process. We ensure intensive inspection for dimensional accuracy, mechanical properties, corrosion resistance, and surface finish of our products. We can provide full traceability, including mill certificates, to ensure durability and performance compliance with international standards.

This tubing is available in a variety of sizes and diameters, typically ranging from 1/8″ to 12″ OD. It offers excellent corrosion resistance, particularly against oxidative and corrosive environments. Ideal for high-pressure applications due to its uniform strength and integrity.

Commonly found in sizes from 1/4″ to 8″ OD, this tubing is produced by welding a seam along its length. It provides good corrosion resistance and is often used in structural and decorative applications. Less uniform in strength compared to seamless tubing but cost-effective.

These tubes are designed for thermal exchange processes and come in sizes ranging from 1/2″ to 4″ OD. They offer superior resistance to heat and corrosion, making them ideal for use in various heating and cooling systems.

Typically available in sizes from 1/8″ to 2″ OD, this tubing is used for precision instrumentation. It features excellent resistance to corrosion and ensures accurate readings in a variety of monitoring and control applications.

Sized from 1″ to 6″ OD, these tubes are specifically designed for boiler systems. They provide high resistance to heat and corrosion, ensuring durability and reliability under high-pressure and high-temperature conditions.

These U-shaped tubes are often used in heat exchangers and come in sizes from 1/2″ to 3″ OD. They are highly resistant to corrosion and thermal stress, making them ideal for applications requiring efficient heat transfer.

: Available in sizes from 1/2″ to 3″ OD, these tubes are used in condenser systems. They provide excellent corrosion resistance and durability against the harsh conditions of cooling and condensation processes.

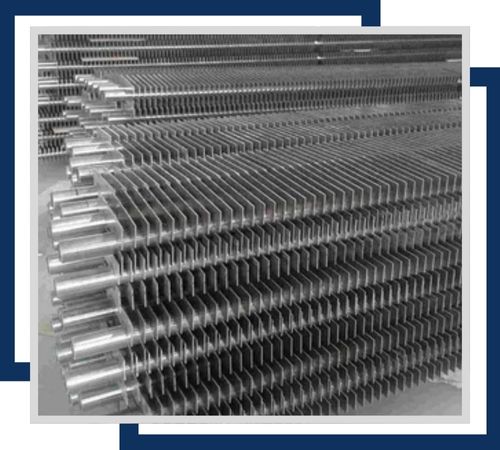

Typically found in sizes from 1″ to 4″ OD, fin tubes are used in heat exchangers and radiators. They offer strong corrosion resistance and enhanced heat transfer efficiency due to their finned surface design.

Thanks to its adaptability and strength, Stainless Steel 304 Tubing finds extensive use across many industries. It’s commonly utilized in food processing equipment, dairy and beverage systems, heat exchangers, architectural frameworks, and marine applications. Moreover, it plays a crucial role in oil and gas, chemical plants, water treatment systems, and pharmaceutical equipment, where hygiene and corrosion resistance are paramount. Offered in both seamless and welded forms, 304 tubing is the go-to choice for structural and fluid-handling applications, ensuring long-lasting and efficient performance even in the most demanding environments.

©2024 Merih Stainless All Rights Reserved.