MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of premium stainless steel products, with a particular focus on precision-engineered Stainless Steel 304H Tubing. This tubing is celebrated for its remarkable resistance to high temperatures, corrosion, and mechanical stress, all thanks to cutting-edge manufacturing techniques and rigorous quality control measures. Catering to sectors like chemical processing, power generation, marine, and pharmaceuticals, MERIH STAINLESS guarantees that every tube adheres to international standards. With a commitment to timely deliveries, customization, and ensuring customer satisfaction, the company has built a solid reputation as a reliable source for stainless steel tubing solutions around the globe.

Stainless Steel 304H Tubing is crafted from a high-carbon austenitic chromium-nickel stainless steel alloy, which enhances its tensile strength and performance in high-temperature environments. Typically, its chemical makeup consists of 18–20% chromium, 8–12% nickel, and 0.04–0.10% carbon, providing excellent resistance to oxidation, corrosion, and thermal stress. On the mechanical side, 304H tubing showcases impressive tensile strength, yield strength, and toughness, maintaining its structural integrity even under extreme high-temperature conditions.

| Alloy 304H Standards | Stainless Steel 304H |

|---|---|

| ASTM A213 Stainless Steel Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| ASTM A249 TP 304H Stainless Steel Welded Tube Size | 6.35 mm OD To 152 mm OD |

| ASTM A269 TP 304H Stainless Steel Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| ASME SA213 TP 304H Stainless Steel Tube wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| SS 304H Length | Single Random, Double Random, Standard & Cut length Tube |

| UNS S30409 Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| ASTM A213 Gr. TP304H Form | ‘U’ bent or Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc |

| ASTM A269 TP 304H Stainless Steel Type | Seamless, ERW, EFW, Welded, Fabricated Tube |

| ASTM A213 Stainless Steel End | Plain End, Beveled End, Treaded Tube |

| ASME SA213 SS 304H Marking | All 304h Stainless Steel Tube are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| ASME SA213TP 304H Stainless Steel Application | Oil Tube, Gas Tube, Fluid Tube, Boiler Tube, Heat exchanger Tube, |

| 304H SS Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Stainless Steel 304H Specialize in | Stainless Steel 304H Capillary Tube & Other Odd Size Alloy 304H Heat Exchanger & Condenser Tube |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 304H | min. | 0.04 | – | – | – | – | 18.0 | – | 8.0 | – |

| max. | 0.10 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | – | ||

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 304H | 515 | 205 | 40 | 92 | 201 |

Contact us to get a quick quote for your requirement.

We assures that all its Stainless Steel 304H Tubing is thoroughly tested for quality and performance. Mechanical properties, corrosion resistance, and dimensional accuracy of the tubing are tested. The following certificates are also provided: Material Test Reports (MTR), 3.1 certificates, and ISO compliance, ensuring industry standards and reliability.

These tubes offer superior corrosion resistance, ideal for high-pressure applications. Sizes typically range from 1/8″ to 24″ in diameter. They provide excellent durability and are used in industries requiring precise tolerances.

Known for its excellent corrosion resistance, this tubing is available in sizes from 1/8″ to 24″. It’s cost-effective for less critical applications and offers good strength and flexibility for various uses.

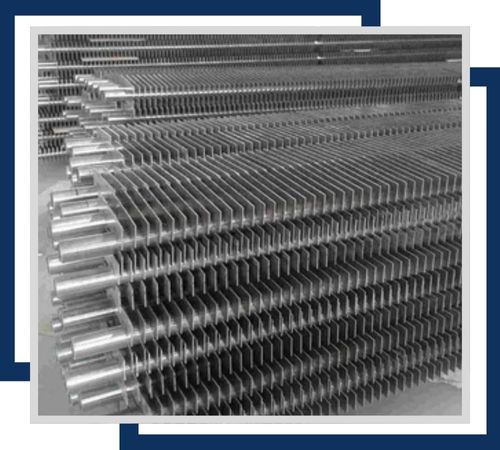

These tubes excel in corrosion resistance and thermal conductivity. Common sizes range from 1/2″ to 1-1/2″ in diameter, designed for efficient heat transfer in industrial applications.

Providing high corrosion resistance, these tubes are typically available in sizes from 1/16″ to 2″. They are crucial for precise instrumentation and control systems in various industries.

These corrosion-resistant tubes come in sizes typically from 1/2″ to 5″ in diameter. They are designed to withstand high temperatures and pressures in boiler systems.

Featuring high corrosion resistance, these U-shaped tubes are available in sizes from 1/2″ to 1-1/2″. They are commonly used in heat exchangers and condensers for efficient thermal management.

Known for its superior corrosion resistance, this tubing ranges from 3/8″ to 1-1/4″ in diameter. It’s used in condensers to efficiently transfer heat and condense steam into water.

These tubes offer excellent corrosion resistance and are available in sizes typically from 1/2″ to 1-1/2″. They are used in applications requiring enhanced heat transfer efficiency due to their extended surface area.

This type of tubing is extensively utilized in industries that demand durable, heat-resistant, and corrosion-resistant piping solutions. It’s perfect for chemical processing equipment, power generation facilities, marine structures, and pharmaceutical machinery. Additionally, you’ll find it in boilers, heat exchangers, industrial piping systems, and high-temperature mechanical setups where both strength and resistance to corrosion are crucial. Available in a variety of sizes, wall thicknesses, and finishes, 304H tubing offers engineers and designers a high-performance option for challenging high-temperature applications.

©2024 Merih Stainless All Rights Reserved.