MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of premium stainless steel products, with a particular focus on precision-engineered Stainless Steel 304I Tubing. This tubing is celebrated for its remarkable corrosion resistance, durability, and mechanical strength, all thanks to cutting-edge manufacturing techniques and rigorous quality control measures. Catering to a variety of sectors including chemical processing, marine, food processing, and pharmaceuticals, MERIH STAINLESS guarantees that every tube adheres to international standards. With a commitment to timely delivery, customization, and customer satisfaction, the company has built a solid reputation as a reliable source of stainless steel tubing solutions around the globe.

Stainless Steel 304I Tubing is crafted from an austenitic chromium-nickel stainless steel alloy, which offers exceptional resistance to corrosion, oxidation, and scaling, even in tough environments. Its typical chemical makeup features 18–20% chromium and 8–12% nickel, ensuring outstanding mechanical properties and durability at moderate temperatures. On the mechanical side, 304I tubing showcases impressive tensile strength, yield strength, and toughness, maintaining its structural integrity in demanding industrial settings.

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 304L | S30400 | 1.4301 | SUS 304 | Z7CN18‐09 | 304S31 | 08Х18Н10 | X5CrNi18-10 |

| SS | 304 |

|---|---|

| Ni | 8 – 11 |

| Fe | Balance |

| Cr | 18 – 20 |

| C | 0.08 max |

| Si | 0.75 max |

| Mn | 2 max |

| P | 0.040 max |

| S | 0.030 max |

| N | – |

| Grade | 304 |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Hardness | |

| Rockwell B (HR B) max | 92 |

| Brinell (HB) max | 201 |

Contact us to get a quick quote for your requirement.

We ensures the highest standards for our stainless steel 304I tubing through rigorous testing and certification processes. Each product undergoes extensive quality testing, including dimensional accuracy, tensile strength and corrosion resistance testing. We offer all relevant certifications, including material testing certificates (MTC) and compliance with international standards.

Stainless Steel 304I Seamless Tubing offers superior strength and corrosion resistance, ideal for high-pressure applications. Available in sizes ranging from 1/8” to 24” in diameter, it is crafted without any welded seams, ensuring durability and leak-proof performance.

Stainless Steel 304I Welded Tubing provides excellent resistance to corrosion and is cost-effective for less demanding applications. Typically available in sizes from 1/8” to 48” in diameter, it features welded seams and is suitable for a wide range of industrial uses.

Stainless Steel 304I Heat Exchanger Tube is designed for optimal thermal transfer and corrosion resistance in various heat exchanger systems. These tubes are available in sizes from 1/4” to 2” in diameter and are perfect for applications requiring efficient heat conduction.

Stainless Steel 304I Instrumentation Tubing is precision-made for high-pressure, high-purity, and corrosive environments. Available in sizes from 1/16” to 2” in diameter, it is ideal for instrumentation and control systems.

Stainless Steel 304I Boiler Tubes are engineered to withstand high temperatures and pressures in boiler applications. Ranging in sizes from 1/2” to 5” in diameter, they offer excellent resistance to oxidation and scaling.

Stainless Steel 304I U-Tubes are bent into a U-shape, perfect for heat exchangers and boiler applications where space efficiency and corrosion resistance are crucial. Sizes typically range from 1/4” to 2” in diameter, providing reliable performance in compact systems.

Stainless Steel 304I Condenser Tube is designed for high-efficiency heat exchange and corrosion resistance in condenser applications. These tubes come in sizes from 1/4” to 2” in diameter and are essential for maintaining system efficiency.

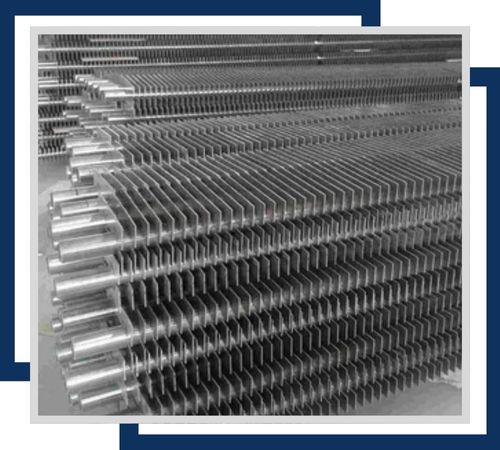

Stainless Steel 304I Fin Tubes feature extended surfaces (fins) to enhance heat transfer and corrosion resistance. Available in various diameters and fin configurations, they are ideal for applications needing increased heat dissipation.

This tubing is extensively utilized in industries that require dependable corrosion resistance and mechanical performance. It’s perfect for chemical processing equipment, food and beverage machinery, pharmaceutical systems, and marine applications. Additionally, 304I tubing finds its place in heat exchangers, industrial piping systems, and architectural projects where durability and corrosion resistance are essential. Offered in a range of sizes, wall thicknesses, and finishes, 304I tubing delivers a high-performance solution for even the most challenging industrial applications.

©2024 Merih Stainless All Rights Reserved.