Stainless Steel 305 Tubing is an austenitic chromium-nickel stainless steel alloy crafted to offer exceptional resistance to corrosion and oxidation across different industrial settings. Typically, its chemical makeup consists of 17–19% chromium and 11–13% nickel, which together provide outstanding mechanical properties and durability even in moderate temperatures and harsh conditions. On the mechanical side, 305 tubing showcases impressive tensile strength, yield strength, and toughness, ensuring it maintains its structural integrity in challenging applications.

Stainless Steel 305 Tubing is an austenitic chromium-nickel stainless steel alloy crafted to offer exceptional resistance to corrosion and oxidation across different industrial settings. Typically, its chemical makeup consists of 17–19% chromium and 11–13% nickel, which together provide outstanding mechanical properties and durability even in moderate temperatures and harsh conditions. On the mechanical side, 305 tubing showcases impressive tensile strength, yield strength, and toughness, ensuring it maintains its structural integrity in challenging applications.

Type: Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes

Grades: TP304, TP304L, TP304H

Size: 1/8” NB to 5” NB, 1/4” OD to 5” OD sizes stainless steel seamless tubes also available

Length: Up to 6 meters, custom cut lengths

Thickness: 1mm to 13mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish: No.1 Pickled Finish, No.4 finish, BA Finish, Electropolished Pipes

Delivery Condition: Hot Finish, Cold Finish, Bright Annealed, Polished, Annealed and Pickled, Passivated, Stress Relived

| Element | Content (%) |

|---|---|

| Iron, Fe | 67 |

| Chromium, Cr | 18 |

| Nickel, Ni | 12 |

| Manganese, Mn | ≤ 2 |

| Silicon, Si | ≤ 1 |

| Carbon, C | 0.12 |

| Phosphorous, P | 0.045 |

| Sulfur, S | 0.030 |

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 585 MPa | 84800 psi |

| Tensile strength, yield (@0.2%) | 260 MPa | 37700 psi |

| Modulus of elasticity | 193 GPa | 28000 ksi |

| Shear modulus | 86 GPa | 12500 ksi |

| Elongation at break (in 50 mm) | 50 | 50 |

| Hardness, Brinell | 80 | 80 |

| Hardness, Knoop (converted from Brinell hardness) | 97 | 97 |

| Hardness, Rockwell B (converted from Brinell hardness) | 45 | 45 |

| Hardness, Vickers (converted from Brinell hardness) | 82 | 82 |

Contact us to get a quick quote for your requirement.

We tests all Stainless Steel 305 Tubing to the international quality standard. Every batch is tested for composition, mechanical properties, and corrosion resistance. The company provides certification for material traceability that complies with ASTM, EN, and other relevant standards to ensure product excellence and reliability.

This tubing comes in a variety of sizes, typically ranging from 1/8″ to 4″ in diameter. Known for its exceptional corrosion resistance and smooth finish, it is ideal for applications requiring high durability and reliability.

Available in sizes from 1/4″ to 6″ in diameter, this tubing features a welded seam for structural strength. It offers excellent corrosion resistance and is commonly used in both industrial and architectural applications.

Designed for heat transfer efficiency, these tubes are generally sized from 1/2″ to 2″ in diameter. They exhibit high resistance to corrosion and are used in heat exchangers for various industrial processes.

Stainless Steel 305 Instrumentation Tubing**: Available in sizes ranging from 1/16″ to 1/2″ in diameter, this tubing is designed for precise instrumentation applications. It offers superior corrosion resistance and is ideal for use in harsh environments and critical measurement systems.

Typically available in sizes from 1″ to 4″ in diameter, these tubes are engineered to withstand high temperatures and pressures. They are highly corrosion-resistant and suitable for boiler systems.

Usually ranging from 1/2″ to 2″ in diameter, these U-shaped tubes are designed for applications such as heat exchangers and condensers. They offer strong corrosion resistance and flexibility in heat transfer systems.

Available in sizes from 1/2″ to 3″ in diameter, these tubes are optimized for use in condensers. They provide excellent resistance to corrosion and scaling, making them ideal for high-performance cooling systems.

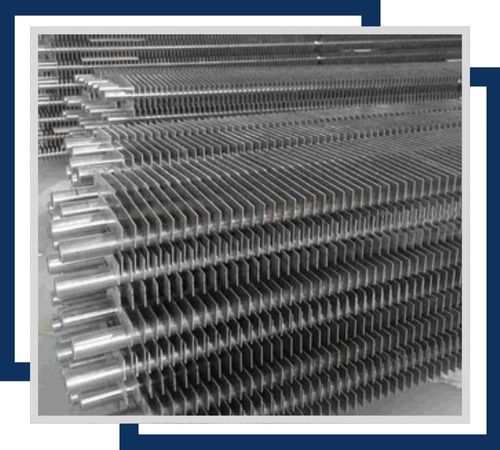

Typically sized from 1″ to 2″ in diameter, these tubes feature finned surfaces for enhanced heat transfer. They are highly resistant to corrosion and are used in various heat exchange and cooling applications.

This tubing is extensively utilized in industries that demand dependable corrosion resistance and mechanical performance. It’s perfect for chemical processing equipment, marine uses, food and beverage processing systems, and pharmaceutical machinery. Additionally, 305 tubing finds its place in heat exchangers, industrial piping systems, and architectural projects where durability and resistance to corrosion are crucial. Offered in a range of sizes, wall thicknesses, and finishes, 305 tubing delivers a high-performance solution for even the most demanding industrial applications.

©2024 Merih Stainless All Rights Reserved.