MERIH STAINLESS, located in the vibrant city of Istanbul, Turkey, stands out as a top-notch manufacturer and supplier of premium stainless steel products, with a particular focus on precision-engineered Stainless Steel 309S Bars. These bars are celebrated for their remarkable resistance to high temperatures, durability, and ability to withstand corrosion. Crafted using cutting-edge production techniques and rigorous quality control measures, MERIH STAINLESS ensures that every bar adheres to international standards. The company proudly serves a variety of industries, including power generation, chemical processing, petrochemical, and aerospace, all while prioritizing timely delivery, customization, and customer satisfaction. This commitment has solidified their reputation as a reliable provider of stainless steel solutions on a global scale.

Stainless Steel 309S Bars are composed of an austenitic chromium-nickel stainless steel alloy with a low carbon content (less than 0.08%), which grants them exceptional resistance to oxidation, scaling, and corrosion even at elevated temperatures. Typically, their chemical makeup features 23–25% chromium and 12–15% nickel, ensuring they possess outstanding mechanical strength and stability under extreme thermal conditions. In terms of mechanics, 309S bars showcase impressive tensile strength, yield strength, and toughness, maintaining their structural integrity even in the most demanding high-temperature environments.

| Grade | Stainless Steel 309S (UNS 30908) |

| Standard | ASTM A276 / ASME SA276 |

| Diameter | 25mm to 152mm dia |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

| Finish | Bright, Polish & Black |

| Type | Round/Square/ Hexagonal/ Rectangular |

Element | Content (%) |

Iron, Fe | 60 |

Chromium, Cr | 23 |

Nickel, Ni | 14 |

Manganese, Mn | 2 |

Silicon, Si | 1 |

Carbon, C | 0.20 |

Phosphorous, P | 0.045 |

Sulfur, S | 0.030 |

Properties | Metric | Imperial |

Tensile strength | 620 MPa | 89900 psi |

Yield strength (@ strain 0.200%) | 310 MPa | 45000 psi |

Izod impact | 120 – 165 J | 88.5 – 122 ft-lb |

Shear modulus (typical for steel) | 77 GPa | 11200 ksi |

Elastic modulus | 200 GPa | 29008 ksi |

Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

Elongation at break (in 50 mm) | 45% | 45% |

Hardness, Brinell | 147 | 147 |

Hardness, Rockwell B | 85 | 85 |

Hardness, Vickers (converted from Rockwell B hardness) | 169 | 169 |

Contact us to get a quick quote for your requirement.

We ensures the highest quality of stainless steel 309S tiles through rigorous testing and certification. Each product undergoes extensive testing, including chemical composition, mechanical properties and durability testing. Certified to accepted industry standards, our breweries deliver efficiency, reliability and compliance, making them ideal for complex applications.

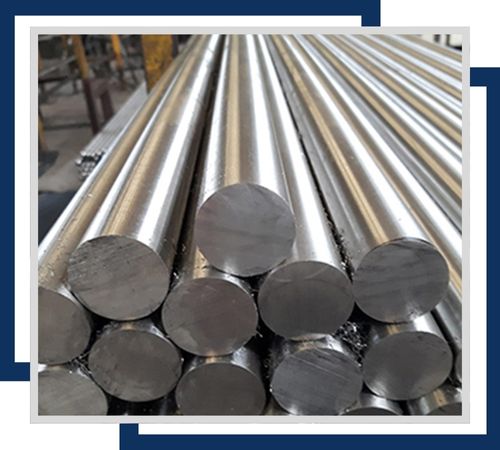

Stainless Steel 309S Round Bars are designed for high-temperature applications, offering exceptional oxidation resistance and durability. They are ideal for components in furnaces, heat exchangers, and other high-heat environments.

Stainless Steel 309S Flat Bars provide outstanding heat resistance and strength, suitable for applications such as heat shields, furnace parts, and structural components exposed to high temperatures and corrosive environments.

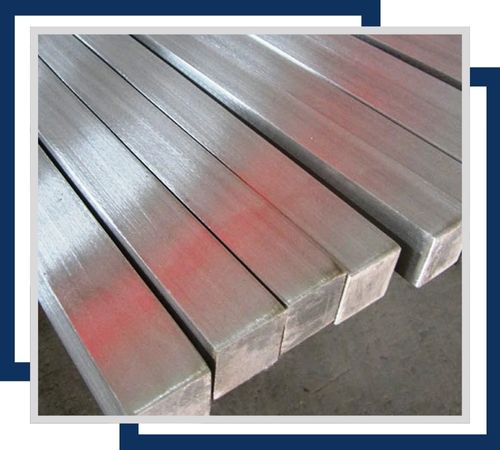

Stainless Steel 309S Square Bars are used in high-temperature settings where heat resistance and durability are critical. They are commonly employed in manufacturing parts for the aerospace industry, industrial equipment, and heat exchangers.

Stainless Steel 309S Rectangular Bars are ideal for high-temperature applications requiring superior oxidation resistance. They are often used in furnace components, structural supports, and industrial parts that endure extreme heat and corrosive conditions.

Stainless Steel 309S Hexagonal Bars are perfect for applications needing high-temperature performance and corrosion resistance. They are utilized in industrial processes, furnace parts, and equipment subjected to severe thermal conditions.

Stainless Steel 309S T-Bars offer excellent heat resistance and strength, making them suitable for high-temperature structural applications. They are commonly used in heat exchangers, support structures, and furnace components.

These Stainless Steel 309S Bars find extensive applications in industries that require both high-temperature durability and corrosion resistance. They are perfect for components in furnaces, heat exchangers, kiln liners, boiler parts, and equipment used in petrochemical processing. Additionally, these bars are utilized in power plants, industrial heaters, and aerospace applications where strength and thermal stability are paramount. Available in a range of sizes, shapes, and finishes, 309S bars offer engineers and designers a high-performance solution tailored for challenging high-temperature applications.

©2024 Merih Stainless All Rights Reserved.