MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of premium stainless steel products, with a particular focus on precision-engineered Stainless Steel 309S Tubing. This tubing is celebrated for its remarkable resistance to high temperatures, durability, and ability to withstand corrosion. It’s crafted using cutting-edge manufacturing techniques and rigorous quality control measures. MERIH STAINLESS caters to a variety of industries, including power generation, chemical processing, petrochemical, and aerospace, ensuring that every tube adheres to international standards. With a commitment to timely delivery, customization, and customer satisfaction, the company has built a reputation as a reliable source for stainless steel tubing solutions around the globe.

Stainless Steel 309S Tubing is composed of an austenitic chromium-nickel stainless steel alloy with a low carbon content (less than 0.08%), which gives it excellent resistance to oxidation, scaling, and corrosion even at high temperatures. Typically, its chemical makeup includes 23–25% chromium and 12–15% nickel, providing outstanding mechanical strength and stability in extreme thermal conditions. On the mechanical side, 309S tubing showcases high tensile strength, yield strength, and toughness, ensuring it maintains its structural integrity in tough, high-temperature industrial settings.

| Thickness | 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Outer Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

| Form | Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes |

| Length | Single Random, Double Random & Required Length |

| End | Plain End, Beveled End, Treaded. |

| ELEMENT | SS 309S |

| NI | 12.0 – 15.0 |

| C | 0.08 max |

| MN | 2.0 max |

| P | 0.045 max |

| S | 0.030 max |

| SI | 1.0 max |

| CR | 22.0 – 24.0 |

| MO | 0.75 max |

| Condition & Grade | Tensile Strength | Yeild Strength | Elognation | Hardness |

|---|---|---|---|---|

| SS 309S | 75 (515) | 30 (205) | 35 | 90 HRB max |

Contact us to get a quick quote for your requirement.

We ensures the highest quality stainless steel 309S tubing through rigorous testing procedures including mechanical, chemical and theoretical testing. Compliance with international standards is demonstrated by industry-standard documentation, such as material test certificates (MTCs). These certifications attest to the durability, strength and performance of the pipe.

Stainless Steel 309s Seamless Tubing is known for its high resistance to oxidation and excellent mechanical properties. It typically comes in diameters ranging from 1/8 inch to 12 inches, with wall thicknesses of 0.5 mm to 10 mm. It offers superior corrosion resistance in high-temperature applications.

Stainless Steel 309s Welded Tubing is ideal for applications requiring good oxidation resistance and strength. It is available in sizes from 1/4 inch to 10 inches in diameter and wall thicknesses from 0.5 mm to 8 mm. This tubing is well-suited for high-temperature environments due to its excellent corrosion resistance.

Stainless Steel 309s Heat Exchanger Tube is designed to handle extreme temperatures and corrosive environments. Common sizes range from 1/2 inch to 3 inches in diameter, with wall thicknesses of 1 mm to 5 mm. It provides excellent thermal conductivity and resistance to oxidation.

Stainless Steel 309s Instrumentation Tubing is used for precise measurement and control applications. It is available in sizes from 1/8 inch to 2 inches in diameter and wall thicknesses from 0.5 mm to 3 mm. This tubing offers strong resistance to high temperatures and corrosive environments.

Stainless Steel 309s Boiler Tubes are engineered for use in high-pressure and high-temperature environments within boilers. Typical sizes are from 1/2 inch to 4 inches in diameter, with wall thicknesses of 1 mm to 8 mm. They exhibit excellent resistance to thermal cycling and oxidation.

Stainless Steel 309s U-Tubes are used in heat exchangers and other applications requiring bending and high thermal resistance. Sizes generally range from 1/2 inch to 2 inches in diameter. They are highly resistant to thermal stress and corrosion.

Stainless Steel 309s Condenser Tube is designed for use in condenser systems where high heat resistance is critical. It comes in sizes from 1/2 inch to 3 inches in diameter and wall thicknesses from 0.5 mm to 4 mm. It provides excellent durability and resistance to corrosion and heat.

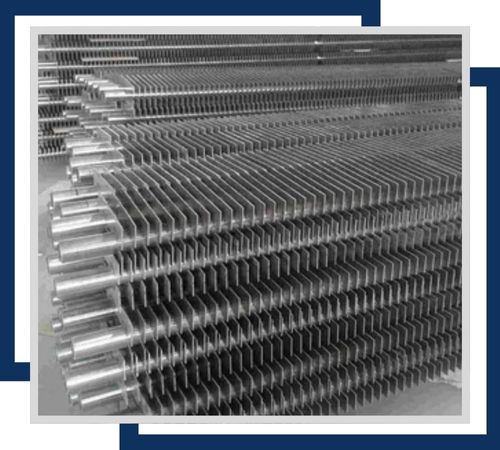

Stainless Steel 309s Fin Tubes are used in applications where enhanced heat transfer is needed, such as in heat exchangers and radiators. Typical sizes are from 1/2 inch to 2 inches in diameter, with various fin lengths and thicknesses. They offer good resistance to oxidation and high temperatures.

This tubing is widely utilized in sectors that demand dependable high-temperature performance and corrosion resistance. It’s perfect for furnace components, heat exchangers, kiln linings, boiler parts, and equipment used in petrochemical processing. Additionally, it finds applications in power plants, industrial heaters, and aerospace projects where durability, thermal stability, and resistance to corrosion are essential. Offered in a range of sizes, wall thicknesses, and finishes, 309S tubing delivers a high-performance solution for engineers and designers tackling demanding high-temperature applications.

©2024 Merih Stainless All Rights Reserved.