MERIH STAINLESS, located in Istanbul, Turkey, has earned a solid reputation as a reliable manufacturer and supplier of top-notch Stainless Steel 314 Fasteners for clients in Dubai, UAE. With a wealth of experience in stainless steel solutions, the company is committed to providing high-performance fasteners that can endure extreme temperatures and tough environments. Renowned for their exceptional quality, durability, and precision engineering, these fasteners comply with global industrial standards. MERIH STAINLESS is continuously strengthening its presence in international markets by offering innovative fastening solutions that ensure reliability and cater to the diverse needs of industries such as petrochemical, power generation, marine, and construction.

These bars are primarily made up of chromium and nickel, featuring around 25% chromium and about 20% nickel, which provides exceptional oxidation and corrosion resistance. Their low carbon content improves weldability and minimizes carbide precipitation, making them ideal for high-temperature applications. Mechanically, these bars boast high tensile strength, excellent creep resistance, and remarkable toughness. They remain stable and durable in environments with temperatures reaching up to 1100°C. This unique blend of properties makes them a reliable option for industrial use, particularly where thermal stability and corrosion resistance are essential.

| Standards | 310S / 1.4845 |

|---|---|

| Designation | ASTM, ASME, AISI A 276 , SA 276, A 479, SA 479, ASTM, ASME A276/SA 479 |

| Range | 3 MM TO 350 MM DIA |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

SS 310S |

0.08 max |

2.0 max |

1.00 max |

0.045 max |

0.030 max |

24.00 – 26.00 |

0.75 max |

19.00 – 21.00 |

53.095 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Contact us to get a quick quote for your requirement.

We ensures that all stainless steel 310S bars undergo rigorous testing and quality control. The products are certified for exceptional durability, corrosion resistance and performance. Certified to international standards, each bar is thoroughly inspected for mechanical, chemical composition and design accuracy to ensure the highest level of reliability

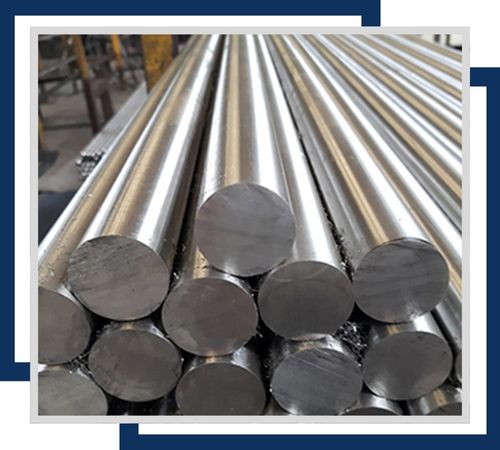

Stainless Steel 310S Round Bars offer excellent heat resistance, available in diameters from 6mm to 500mm. These bars are ideal for high-temperature applications such as furnace parts and heat exchangers, providing durability and strength.

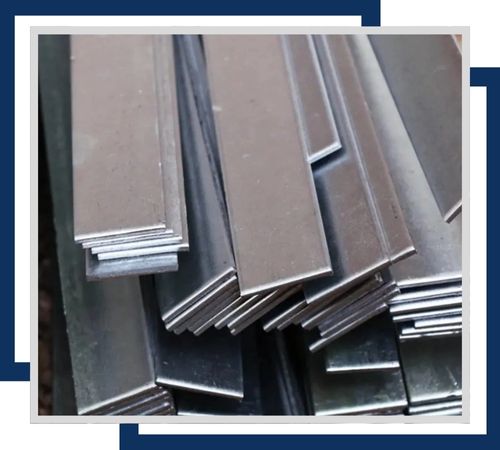

Stainless Steel 310S Flat Bars, available in thicknesses from 3mm to 100mm and widths from 12mm to 300mm, are perfect for applications requiring high thermal stability. These bars are used in the construction, automotive, and industrial sectors.

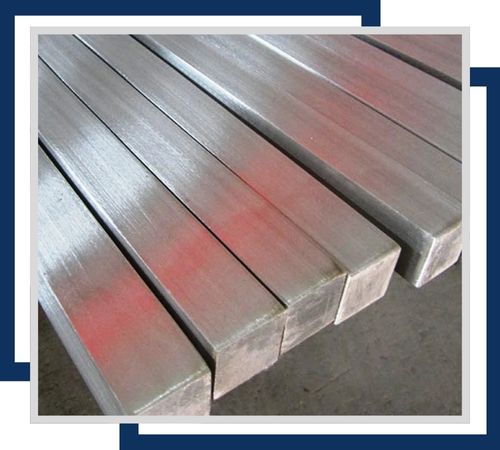

Stainless Steel 310S Square Bars, with sizes ranging from 6mm to 150mm, provide excellent mechanical properties and heat resistance. Ideal for structural and architectural applications, these bars ensure durability in demanding environments.

Stainless Steel 310S Rectangular Bars are designed for construction and industrial applications, available in thicknesses from 3mm to 100mm and widths from 10mm to 200mm. They offer superior durability and thermal stability for high-temperature environments.

Stainless Steel 310S Hexagonal Bars, available in sizes from 6mm to 100mm across flats, are perfect for fasteners and fittings. These bars provide high strength and excellent resistance to high temperatures, making them suitable for industrial applications.

Stainless Steel 310S T Bars offer robust structural support, available in sizes from 20mm to 100mm in width. These bars are ideal for construction and architectural applications, providing high strength and thermal stability.

Stainless Steel 310S Bars find extensive use in industries that demand top-notch performance in high-temperature and corrosive settings. They are commonly found in furnace components, heat exchangers, kilns, and power plant equipment due to their ability to endure oxidation and thermal stress. In the petrochemical and refinery sectors, they are utilized in piping systems and processing units where durability and resistance to aggressive media are crucial. Moreover, these bars are also employed in construction, cement, and marine industries, ensuring reliable performance and structural integrity even in harsh and challenging conditions.

©2024 Merih Stainless All Rights Reserved.