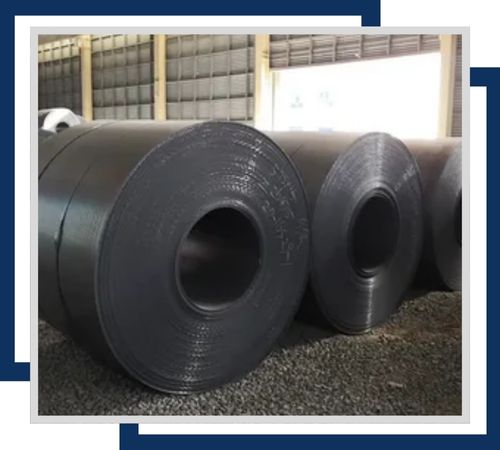

MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of premium stainless steel products, with a particular focus on precision-engineered Stainless Steel 310S Coils. These coils are celebrated for their remarkable resistance to high temperatures, durability, and ability to withstand corrosion. They are crafted using cutting-edge manufacturing techniques and rigorous quality control measures. MERIH STAINLESS caters to various sectors, including power generation, chemical processing, petrochemical, and aerospace, ensuring that every coil adheres to international standards. With a commitment to timely delivery, customization, and customer satisfaction, the company has built a reputation as a reliable provider of stainless steel coil solutions around the globe.

Stainless Steel 310S Coils are made from an austenitic chromium-nickel stainless steel alloy with a low carbon content (less than 0.08%), which gives them excellent resistance to oxidation, scaling, and corrosion even at high temperatures. Typically, their chemical makeup includes 24–26% chromium and 19–22% nickel, which guarantees impressive mechanical strength and stability under extreme thermal conditions. In terms of mechanics, 310S coils showcase high tensile strength, yield strength, and toughness, ensuring they maintain their structural integrity when faced with thermal stress and high-temperature environments.

| Standard | ASTM A240, ASME SA240 |

| Thickness | 0.1mm to 12 mm Thk |

| Coil Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm etc. |

| Coil Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm etc. |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sandblast, Brush, etching. |

| Finish | Hot rolled (HR), Cold rolled (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated), Galvanized etc. |

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 310s | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24 – 26 | 0.75 max | 19 – 21 | 53.095 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |

Contact us to get a quick quote for your requirement.

SS 310s slitting coils are primarily used for applications involving high temperature with excellent resistance to oxidation and corrosion. Such products are generally ideal for application in furnace components, heat exchangers, and chemical processing equipment.

The SS 310s hot rolled coils have been designed especially for high temperature applications with outstanding resistance to oxidation and corrosion. They are normally applied in various furnace components and industrial equipment on account of the strength and resistance offered by them.

SS 310s cold rolled coils have a much better surface finish and dimensional tolerance than hot rolled coils. Such coils are typically used in demanding applications where precision tolerances, excellent corrosion resistance is required, as in chemical processing, heat exchangers, and high temperature environments. I

Stainless Steel 310s HR slitting coils are hot-rolled and slit to widths. These provide excellent resistance to high temperature and corrosion. These are ideal for furnace components, heat exchangers, etc., in any demanding industrial applications.

Stainless Steel 310s slitting coils are slit to precise widths from hot rolled or cold rolled sheets. It offers high temperature resistance and corrosion resistance. They are ideal for furnace parts and heat exchangers.

AISI 310s slitting coils are cut from hot-rolled stainless steel, with excellent high-temperature and corrosion resistance. These are ideal for furnace parts, heat exchangers, and other high-stress industrial applications.

These coils are widely utilized in industries that demand reliable performance at high temperatures and resistance to corrosion. They are perfect for applications such as furnace components, heat exchangers, kiln linings, boiler parts, and equipment used in petrochemical processing. Additionally, 310S coils find their place in power plants, industrial heaters, and aerospace applications where durability, thermal stability, and oxidation resistance are essential. Available in a range of widths, thicknesses, and finishes, these coils offer engineers and designers a high-performance solution for challenging high-temperature applications.

Such stainless steel 310S coils have become exceptionally used in high temperature applications due to the excellent heat resistance and durability. The materials are widely used in furnace parts, heat exchangers, and gas turbines, where the ability of extreme heat and oxidation is possible. They are also used in chemical processing, petrochemical industries, and as components of industrial oven. Their high strength and resistance to thermal expansion have made their use in applications wherein maintenance of structure at high temperatures is essential.

©2024 Merih Stainless All Rights Reserved.