MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of premium stainless steel products, with a particular focus on precision-engineered Stainless Steel 310S Tubing. This tubing is celebrated for its remarkable resistance to high temperatures, durability, and ability to withstand corrosion. Crafted using cutting-edge production techniques and rigorous quality control measures, MERIH STAINLESS caters to various industries, including power generation, chemical processing, petrochemical, and aerospace. The company is committed to ensuring that every tube adheres to international standards, while also prioritizing timely delivery, customization, and customer satisfaction, solidifying its reputation as a reliable source of stainless steel tubing solutions around the globe.

Stainless Steel 310S Tubing is an austenitic chromium-nickel stainless steel alloy with a low carbon content (less than 0.08%), which grants it excellent resistance to oxidation, scaling, and corrosion even at elevated temperatures. Typically, its chemical makeup consists of 24–26% chromium and 19–22% nickel, providing exceptional mechanical strength and stability in high-temperature settings. On the mechanical side, 310S tubing showcases impressive tensile strength, yield strength, and excellent ductility, ensuring it maintains its structural integrity under thermal stress and during extended high-temperature use.

| Specifications | ASTM A/ASME SA213/A249/A269/A312/A358 CL. I to V ASTM A789/A790 |

| Size | Seamless 310S Pipes and Tubes – 1/2″ NB – 16″ NB |

| ERW 310S Pipes and Tubes | 1/2″ NB – 24″ NB |

| EFW 310S Pipes and Tubes | 6″ NB – 100″ NB |

| Wall Thickness | Schedule 5S – Schedule XXS. |

| Dimensions | ASTM, ASME and API |

| Schedule | SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Length | Single Random, Double Random & Cut Length. |

| Form | Round, Square, Rectangular, Hydraulic Etc. |

| Element | SS 310S |

|---|---|

| Ni | 14 max |

| Cr | 23 max |

| C | 0.20 max |

| Fe | 60 max |

| Mn | 2 max |

| Si | 1 max |

| S | 0.030 max |

| P | 0.045 max |

| Element | SS 310S |

|---|---|

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 45000 , MPa – 205 |

| Elongation | 45 % |

Contact us to get a quick quote for your requirement.

We offers complete testing and certification of its stainless steel 310S tubing. Each tube undergoes rigorous quality control procedures, including dimensional testing, mechanical testing and corrosion resistance testing. Certificates of compliance, mill test reports (MTRs), and material inspection capabilities are provided to ensure full compliance with industry standards and specifications

Stainless Steel 310s Seamless Tubing, known for its excellent corrosion resistance, typically comes in sizes ranging from 1/8″ to 24″ in diameter. This tubing is ideal for high-temperature applications and provides a smooth, continuous surface without any welds.

Stainless Steel 310s Welded Tubing offers good corrosion resistance and is available in sizes from 1/8″ to 36″ in diameter. It is manufactured by welding strips of stainless steel and is suitable for both structural and fluid transport applications.

Stainless Steel 310s Heat Exchanger Tube, resistant to oxidation and corrosion, typically ranges from 1/4″ to 3″ in diameter. It is designed for high-temperature service in heat exchangers, ensuring efficient thermal transfer.

Stainless Steel 310s Instrumentation Tubing, with high corrosion resistance, comes in sizes from 1/8″ to 1″ in diameter. It is used in precise instrumentation applications, providing accurate and reliable measurements.

Stainless Steel 310s Boiler Tubes, known for their excellent corrosion resistance, are available in sizes from 1/8″ to 5″ in diameter. These tubes are used in boiler systems, offering high-temperature performance and durability.

Stainless Steel 310s U-Tubes, offering good corrosion resistance, typically range in sizes from 1/4″ to 2″ in diameter. These tubes are bent into U shapes for heat exchangers and other applications where compact design is essential.

Stainless Steel 310s Condenser Tube, resistant to corrosion and high temperatures, comes in sizes from 1/8″ to 2″ in diameter. It is used in condensers to efficiently condense steam and other vapors back into liquid form.

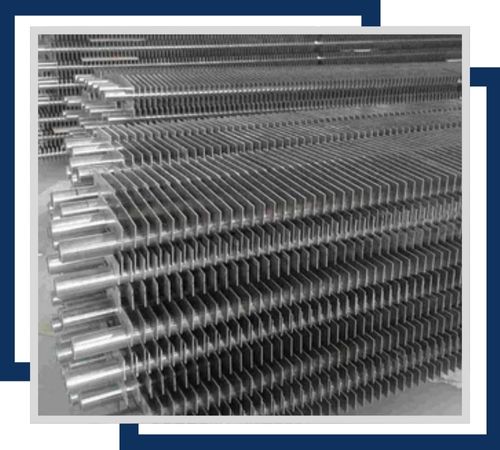

Stainless Steel 310s Fin Tubes, with high corrosion resistance, are available in sizes from 1/4″ to 1″ in diameter. These tubes have fins attached to their surface to enhance heat transfer efficiency in heat exchangers.

Stainless Steel 310S tubing is applied in highly corrosive and high-temperature conditions because of its excellent oxidation resistance and up to 1150°C (2100°F) temperature tolerance. It finds its applications in furnace parts, heat exchangers, and other chemical processing plant components, petrochemical industries, and power plants. The tubing is also ideal for manufacturing incinerators, food processing equipment, and pharmaceutical devices. Furthermore, the alloy resists scaling and thermal fatigue well and can be applied to welding and structural uses or any industry where strength and resistance are highly valued at high temperatures.

©2024 Merih Stainless All Rights Reserved.