MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of premium stainless steel products, with a particular focus on precision-engineered Stainless Steel 316H Tubing. This tubing is celebrated for its remarkable resistance to corrosion, impressive performance at high temperatures, and overall durability. Crafted with cutting-edge production methods and rigorous quality control, each tube is designed to meet international standards. MERIH STAINLESS caters to a variety of industries, including chemical processing, power generation, marine, and pharmaceuticals, ensuring timely delivery, customization, and a commitment to customer satisfaction. This dedication has solidified the company’s reputation as a reliable source for stainless steel tubing solutions around the globe.

Stainless Steel 316H Tubing is an austenitic alloy that combines chromium, nickel, and molybdenum, featuring a higher carbon content (0.04–0.10%) that boosts its strength at elevated temperatures while still offering excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. Typically, its chemical makeup includes 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, which together provide outstanding corrosion resistance in challenging chemical, marine, and industrial settings. On the mechanical side, 316H tubing showcases high tensile strength, yield strength, and ductility, ensuring it maintains its structural integrity even under thermal stress and pressure.

Specifications : ASTM A213, A312, A269, A358 / ASME SA213, SA312, SA269, SA358

Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24″ NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type : Seamless / ERW / Welded / Fabricated / CDW

Form : Round Tubes, Square Tubes, Rectangular Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

Outside Finish : 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Tubes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 316H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 | 68.89 min |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Contact us to get a quick quote for your requirement.

We ensures high-quality Stainless Steel 316H Tubing through hydrostatic, ultrasonic, PMI (Positive Material Identification), and intergranular corrosion tests. Every batch is inspected in detail to meet the standards of ASTM and ASME. ISO, EN, and NACE certified, all products are delivered with material test reports and compliance certificates.

Stainless Steel 316H Seamless Tubing is available in sizes ranging from 1/8″ to 24″ in diameter. Known for its superior corrosion resistance, it is ideal for high-temperature applications. The absence of welds ensures a smooth finish and higher strength.

Stainless Steel 316H Welded Tubing is available in sizes from 1/8″ to 72″ in diameter. It offers excellent corrosion resistance and is suitable for a variety of applications, including chemical and petrochemical industries. The welding process allows for cost-effective production of longer lengths.

Stainless Steel 316H Heat Exchanger Tubes come in sizes from 1/2″ to 12″ in diameter. They are designed for optimal heat transfer and corrosion resistance, making them ideal for high-temperature environments. These tubes are essential components in heating and cooling systems.

Stainless Steel 316H Instrumentation Tubing is available in sizes from 1/8″ to 1″ in diameter. It offers high corrosion resistance and precise dimensional tolerances, making it perfect for use in critical instrumentation and control systems. These tubes ensure reliable performance under high pressure.

Stainless Steel 316H Boiler Tubes range in size from 1/2″ to 5″ in diameter. They provide excellent corrosion resistance and can withstand high temperatures and pressures. These tubes are essential in the construction of boilers and pressure vessels.

Stainless Steel 316H U-Tubes are available in sizes from 1/2″ to 1-1/2″ in diameter. They are specifically designed for heat exchanger applications where space is limited, offering superior corrosion resistance. The U-shape allows for efficient heat transfer in compact spaces.

Stainless Steel 316H Condenser Tubes come in sizes from 1/4″ to 2″ in diameter. They provide excellent corrosion resistance and are used in condensers and evaporators. These tubes are critical for effective heat exchange in various industrial processes.

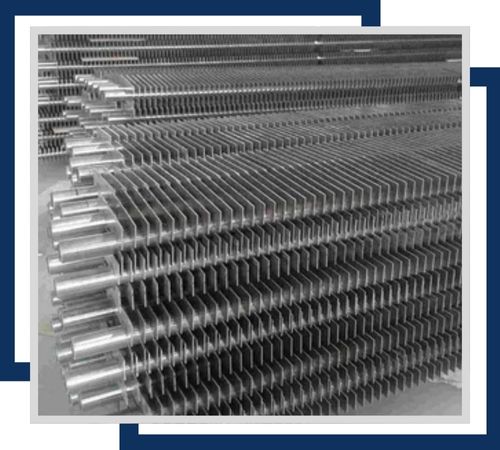

Stainless Steel 316H Fin Tubes are available in sizes from 1/2″ to 2″ in diameter. They are designed with fins to increase the surface area for better heat transfer, offering high corrosion resistance. These tubes are ideal for heat exchangers and air conditioning systems.

This versatile Stainless Steel 316H Tubing is extensively utilized in sectors that demand high-temperature performance and corrosion resistance. It’s perfect for chemical processing equipment, power generation systems, heat exchangers, marine applications, and pharmaceutical machinery. Additionally, you’ll find it in boilers, condensers, industrial piping systems, and high-temperature processing lines, all while guaranteeing durability and a long service life. Offered in a range of sizes, wall thicknesses, and finishes, 316H tubing delivers engineers and designers a high-performance solution for critical applications where both strength and corrosion resistance are vital.

©2024 Merih Stainless All Rights Reserved.