MERIH STAINLESS, located in Istanbul, Turkey, stands out as a leading manufacturer and supplier of top-notch stainless steel products, with a special focus on precision-engineered Stainless Steel 317L Tubing. Known for its unwavering dedication to quality, MERIH STAINLESS merges cutting-edge production techniques with strict quality control measures to provide tubing solutions that are not only durable and corrosion-resistant but also reliable. The company caters to various sectors, including chemical processing, pharmaceuticals, marine, and food processing, ensuring that every tube adheres to international standards. With a strong emphasis on customer satisfaction, prompt delivery, and tailored solutions, MERIH STAINLESS has earned a reputation as a dependable partner for stainless steel tubing needs around the globe.

Stainless Steel 317L Tubing is an austenitic alloy made of chromium, nickel, and molybdenum, boasting superior corrosion resistance compared to its 316L counterpart. Typically, its chemical makeup consists of 16–18% chromium, 12–15% nickel, 3–4% molybdenum, and a low carbon content (<0.03%) to improve weldability and minimize carbide precipitation. On the mechanical side, 317L tubing showcases impressive tensile strength, yield strength, and ductility, maintaining its stability across a broad temperature range. Its remarkable resistance to pitting, crevice corrosion, and stress corrosion cracking makes it perfect for challenging environments. Plus, the tubing is highly formable and can be crafted to exact dimensions without sacrificing its structural integrity.

| ASTM A213 / ASME SA 213 | Standard Specification for SS TP 317L Seamless Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes |

| Shapes | ASME SA213 TP317L Round, Rectangular, Square, Hydraulic, Straight, “U” Shape, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type | Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100% X Ray Welded |

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Surface Finish | BA, 2B, No.4, No.1, No.3, No.8, 8K, HL, 2D, 1D, Mirror Polished, 180G, 320G, 400G Satin/ Hairline, 400G, 500G, 600G or 800G Mirror finish DIN 1.4438 Stainless Steel 317L Tubing or Custom Finish as per customer’s specification |

| Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS, SCH XS |

| Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN |

| Relevant Standard | ASTM A213, ASTM A312, ASTM A269, ASTM A778, ASTM A554, ASTM A249, ASTM A269, ASTM A270, ASTM A789, DIN 17456, DIN17457, DIN 17459, JIS G3459, JIS G3463, GOST9941, EN10216, BS3605, GB13296 |

| Value Added Services |

|

| SS 317L | Maximum |

|---|---|

| Ni | 11 – 15 |

| C | 0.035 Maximum |

| Mn | 2 Maximum |

| P | 0.040 Maximum |

| S | 0.03 Maximum |

| Si | 1 Maximum |

| Cr | 18 – 20 |

| Mo | 3 – 4 |

| N | – |

| Element | AISI 317L |

|---|---|

| Density | 8.0 g/cm3 |

| Melting Range | 1454 °C (2650 °F) |

| Tensile Stress | Psi – 75000 , MPa – 515 |

| Yield Stress (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35 % |

| Hardness (Brinell) | – |

Contact us to get a quick quote for your requirement.

We offers thorough testing and certification of its stainless steel 317L tubing, ensuring the highest quality and performance. Each batch undergoes rigorous inspection, including mechanical testing, chemical analysis and pressure testing. Certifications are issued, proving compliance with international standards as well as good reliability and customer-specific requirements.

Stainless Steel 317L seamless tubing is a corrosion-resistant alloy ideal for chemical, pharmaceutical, and food processing industries, offering superior strength, weldability, and durability in harsh environments.

Stainless Steel 317L welded tubing is highly resistant to corrosion, ideal for chemical, pharmaceutical, and food processing industries, offering excellent weldability, strength, and durability in demanding environments.

Stainless Steel 317L heat exchanger tubes provide excellent resistance to corrosion and high temperatures, making them ideal for use in chemical, petrochemical, and power generation industries with superior heat transfer performance

Stainless Steel 317L instrumentation tubing offers high corrosion resistance and excellent durability, making it ideal for precise applications in chemical, petrochemical, and pharmaceutical industries, ensuring reliable performance in demanding environments.

Stainless Steel 317L boiler tubes are designed for high-temperature and corrosive environments, providing exceptional resistance to oxidation and scaling, making them ideal for industrial boilers and heat exchangers.

Stainless Steel 317L U-tubes offer high corrosion resistance and durability, ideal for heat exchangers and industrial applications requiring exceptional performance under harsh conditions and high temperatures.

Stainless Steel 317L condenser tubes provide excellent resistance to corrosion and high temperatures, making them perfect for use in heat exchangers and cooling systems in chemical and petrochemical industries.

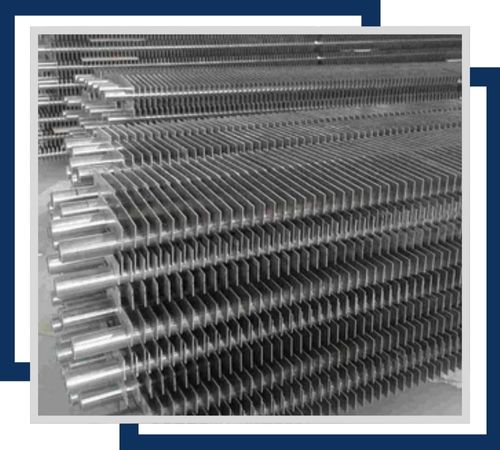

Stainless Steel 317L fin tubes enhance heat transfer efficiency with superior corrosion resistance, making them ideal for applications in heat exchangers, air coolers, and industrial processes requiring reliable performance.

Stainless Steel 317L Tubing is extensively used in industries that demand high corrosion resistance and durability. It’s perfect for chemical processing equipment, heat exchangers, and pharmaceutical manufacturing systems, where aggressive chemicals are often present. The tubing is also widely utilized in marine settings, desalination plants, and food processing, ensuring both hygiene and longevity. Its exceptional strength and corrosion resistance make it a great fit for medical devices, architectural projects, and industrial piping systems. Customizable in size and specifications, it meets a variety of application needs.

©2024 Merih Stainless All Rights Reserved.