MERIH STAINLESS, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of high-quality stainless steel products. Their Stainless Steel 348H Tubing is crafted to excel in high-temperature and corrosive settings. With precision engineering and adherence to international standards, this tubing offers a perfect blend of durability, strength, and thermal stability, ensuring it lasts in critical applications. MERIH STAINLESS prioritizes quality, reliability, and prompt delivery, making these tubes perfect for sectors like power generation, chemical processing, petrochemical, and aerospace. They efficiently transport fluids and gases while maintaining their integrity even in extreme conditions.

Stainless Steel 348H Tubing is crafted from high-temperature austenitic stainless steel, featuring 20–25% chromium, 20–25% nickel, 0.04–0.10% carbon, along with small amounts of manganese, silicon, and titanium for stabilization. This unique blend offers outstanding oxidation resistance, thermal creep strength, and scaling resistance at high temperatures. In terms of mechanics, 348H Tubing boasts a tensile strength exceeding 515 MPa, a yield strength around 205 MPa, and remarkable creep rupture resistance. The combination of high-temperature stability, corrosion resistance, and toughness ensures this tubing performs reliably in demanding industrial and engineering settings.

| Sizes: | 1/8″ to 24″ |

| ASTM A312 Steel grades: | TP304/304L/304H |

| ASTM A312 Schedules: | STD, XS, XXS, SCH5S, SCH10/10S, SCH20, SCH30, SCH40/40S, SCH60, SCH80/80S, SCH100, SCH120, SCH140, SCH160 |

| Standards: | ASTM A312, ASME SA312 |

| Lengths: | SRL and DRL 5meters up to 11meters available from Stock or Production. |

| Ends: | Plain/Bevelled |

| AISI 348H Chemical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | Si | Cr | Ni | Cb | Co | Ta |

| 0.08 Max | 2.00 Max | 0.045 Max | 0.030 Max | 1.00 Max | 17.0-20.0 | 9.0-13.0 | 1.10 Max | 0.20 Max | 0.10 Max |

| Yeild strength | Tensile strength | Elongation | Reduction |

| Min 0.2% Mpa | Min Mpa | Min % | Min % |

| 205 | 515 | 30 | 50 |

Contact us to get a quick quote for your requirement.

We maintains the maximum quality levels by conducting a serious testing and testing certification process to ensure Stainless Steel 348H Tubing quality. Each of the products, before they reach the customers’ doorstep, will undergo proper tests including dimensional verification, chemical analysis, and some mechanical testing procedures. The respective company issues an MTR ensuring the material conformity to international norms and specifications.

This tubing is seamless, available in various sizes with precise dimensions. It offers excellent corrosion resistance suitable for high-temperature applications.

Welded for structural integrity, available in a range of sizes. Known for its robust construction and corrosion resistance, ideal for industrial applications.

Designed specifically for heat transfer applications, available in customized sizes. Offers superior resistance to corrosion and thermal stress.

Precision tubing with controlled dimensions for instrumentation and control systems. Provides high corrosion resistance and reliability in sensitive environments.

Engineered for high-pressure boiler systems, available in standard and custom sizes. Resistant to corrosion and oxidation, ensuring long-term performance.

U-shaped tubes used in heat exchangers and condensers, available in diverse dimensions. Offers excellent resistance to corrosion and stress cracking.

Specifically designed for condenser applications, available in various diameters. Provides superior corrosion resistance and heat transfer efficiency.

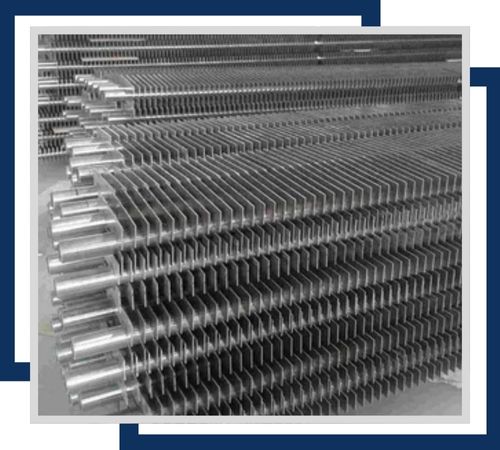

Tubes with extended surface area for enhanced heat transfer efficiency, available in multiple configurations. Offers exceptional resistance to corrosion and oxidation.

Stainless Steel 348H Tubing finds extensive use in industries that demand high-temperature durability and corrosion resistance. You’ll commonly see it in boilers, heat exchangers, pressure vessels, chemical reactors, and piping systems within power plants and petrochemical sectors. Additionally, these tubes are utilized in aerospace components, refinery equipment, and other critical applications where they face prolonged exposure to high temperatures and aggressive chemicals. 348H Tubing is particularly well-suited for transporting fluids and gases, ensuring efficiency and reliability in challenging environments.

©2024 Merih Stainless All Rights Reserved.