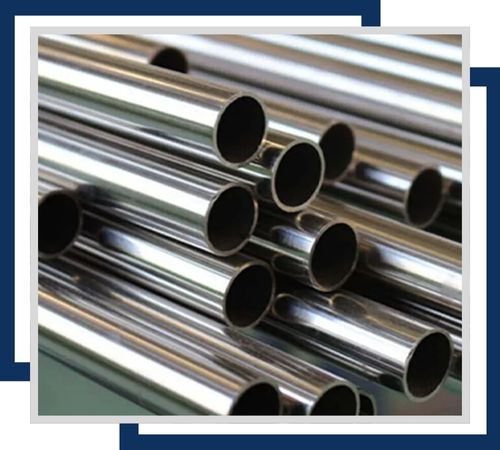

MERIH STAINLESS, based in Istanbul, Turkey, is a reputable manufacturer and supplier of Stainless Steel 405 pipes, delivering top-notch solutions for industries that need corrosion resistance, heat tolerance, and durability—all at a budget-friendly price. Thanks to cutting-edge production technology and rigorous quality control, MERIH STAINLESS guarantees that each pipe adheres to international standards for precision, mechanical performance, and reliability. These Stainless Steel 405 pipes are designed for tough applications, providing excellent dimensional stability and resistance to scaling and oxidation in high-temperature and moderately corrosive settings. They come in a variety of sizes and specifications, catering to sectors like automotive, chemical, power generation, and industrial.

Stainless Steel 405 pipes are made from ferritic stainless steel alloys, primarily consisting of iron and chromium, with a low carbon content that minimizes sensitization and enhances weldability. This unique composition offers solid corrosion and oxidation resistance, along with moderate mechanical strength. The ferritic structure guarantees dimensional stability, mechanical integrity, and long-lasting durability under thermal and mechanical stress, making these pipes a great choice for industrial and engineering applications that demand reliable, cost-effective performance.

| Specifications | : | ASTM A268 / SA 268 |

| Dimensions | : | ASTM, ASME and API |

| Size | : | 1/4″ (6.25mm) to 8″ (203mm), WT 0.02″ (0.5mm) to 0.5″(12mm) |

| Schedule | : | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Specialized in | : | Large Diameter Size |

| Length | : | Single Random, Double Random & Cut Length. |

| Form | : | Round, Square, Rectangular, Hydraulic Etc |

|

|

C |

Cr |

Fe |

Mn |

Si |

S |

P |

Ni | Al |

|

405 |

0.08 max |

min: 11.5 max: 14.5 |

balance |

1.0 max |

1.0 max |

0.03 max |

0.04 max |

0.50 max |

min: 0.1 max: 0.3 |

Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

405 | 60 (415) | 25 (170) | 20 | 179 | 88 |

Contact us to get a quick quote for your requirement.

We ensures high standards of quality through rigorous testing and certification. Testing and certifications in chemical analysis, mechanical testing, and dimensional checks on every pipe. Our stainless steel 405 pipes are certified to be long-lasting, resistant to corrosion, and perform at maximum levels; this is due to the industry-specific regulations and specifications of clients about reliability.

Stainless Steel 405 ERW (Electric Resistance Welded) pipes are made by welding stainless steel strips, offering good heat resistance and durability, suitable for automotive exhaust systems and high-temperature applications.

Stainless Steel 405 EFW (Electric Fusion Welded) pipes are created through fusion welding of stainless steel plates, providing high strength and heat resistance, ideal for large-diameter, high-temperature applications.

Stainless Steel 405 LSAW (Longitudinally Submerged Arc Welded) pipes are produced using submerged arc welding, offering strong heat resistance and durability for large-diameter, high-temperature industrial applications.

Stainless Steel 405 Seamless pipes are manufactured without welding, providing uniform strength and excellent heat resistance, ideal for automotive exhaust systems, heat exchangers, and high-temperature applications.

Stainless Steel 405 Welded pipes are made by welding stainless steel sections, offering good heat resistance and strength, suitable for exhaust systems and high-temperature industrial processes.

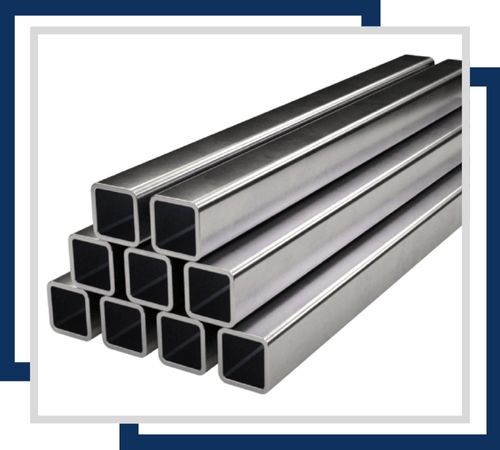

Stainless Steel 405 Square pipes feature a square cross-section, providing structural support and heat resistance for applications in automotive and industrial sectors requiring durability and high-temperature performance.

These Stainless Steel 405 pipes find extensive use in industries that require piping solutions that can withstand heat, resist corrosion, and maintain mechanical reliability. They’re perfect for automotive exhaust systems, boiler tubes, furnace components, heat exchangers, and chemical processing equipment. Additionally, they’re utilized in power generation facilities and industrial machinery that face high temperatures and moderately corrosive environments. Their robust durability, resistance to scaling, and long service life help cut down on maintenance needs while ensuring dependable operation. Stainless Steel 405 pipes offer efficient, reliable, and cost-effective solutions for essential industrial applications.

©2024 Merih Stainless All Rights Reserved.