MERIH STAINLESS, based in Istanbul, Turkey, is a reliable manufacturer and supplier of Stainless Steel 410 bars, delivering top-notch solutions for industries that need materials with corrosion resistance, heat tolerance, and mechanical strength. Thanks to their cutting-edge manufacturing techniques and strict quality control measures, MERIH STAINLESS guarantees that each bar meets international standards for performance, precision, and dependability. These Stainless Steel 410 bars are designed for tough applications, boasting impressive hardness, wear resistance, and stability even at high temperatures. They come in various sizes and specifications, making them popular choices in the automotive, chemical, power generation, and industrial sectors.

Stainless Steel 410 bars are martensitic stainless steel alloys primarily made of iron, chromium, and carbon, offering moderate corrosion resistance along with good tensile strength and hardness. The carbon content allows for heat treatment, which enhances their mechanical properties like toughness, wear resistance, and fatigue performance. Their martensitic structure ensures they maintain their shape and reliability under both thermal and mechanical stress, making them perfect for demanding industrial and engineering tasks.

| Specification | ASTM A479/ SA479 ASTM A276/ ASME SA276 |

|---|---|

| Grade | Stainless Steel 410 (UNS S41000) |

| Hex Bar size | 18 to 57mm (11/16″ – 2-3/4″) |

| Round bar size | OD 4mm to 500mm |

| Square bar size | 18mm to 47mm (11/16″- 1-3/4″) |

| Billet Size | 1/2″- 495mm Dia. |

| Rectangles Size | 33 x 30mm – 295 x 1066mm |

| Bright Bar | OD 4mm to 100mm |

| Tolerance | K12 H12, K10, H9, H11, H8, H13K9, H10, K11, or as per need |

| Flat bar size | 1/2” to 10” in thickness of 2 to 150mm |

| Angle bar size | 3*20*20~12*100*100 |

| Finish | centreless ground, Cold (bright) drawn, hot rolled, peeled, smooth turned, hot rolled annealed, slit rolled edge, Bright, Rough Turned, Grinding, Polish & Black |

| Form | Flat Bar, Hollow, Round, Square, Triangle, Rectangle, Half Round Bar, Rod, T-Bar, Precision Ground Bar, Hex (A/F), Blocks, Channel Bar, Threaded, Round Rod, Billet, Profiles, I/H Bar, Ingot, Rings, Forging etc. |

| Technique | 440C Stainless Steel Hot Rolled, Cold Drawn, Rod, Forged Round Bar, Cold Rolled |

| Condition | annealed, Hardened & tempered |

| Section | 3.0 -12.0 mm thickness, 80 x 40 to 150 x 75mm section |

| Channel Bar | 5.0 – 6.0mm thickness |

| Surface | Bright, Cold Drawn, Hot Rolled Pickled, Sand Blasting Finished, Polished, Hairline |

| Hollow Bar | 32mm OD x 16mm ID – 250mm OD x 200mm ID |

| Grade | AISI | Stainless Steel Bolts & Nuts Chemical Composition (% maxima unless stated) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu | ||||||

| 410 | SS 410 | 0.09-0.15 | 1.0 | 1.0 | 0.05 | 0.03 | 11,5 – 14,0 | – | 1 | – | ||||

| Type | Tensile Strength | Yield Strength (0.2% offset) | Elongation in 2” (50.80mm) % | Hardness (Rockwell) | ||

|---|---|---|---|---|---|---|

| Ksi | MPa | Ksi | MPa | |||

| 410 | 70 | 483 | 45 | 310 | 25 | B80 |

Contact us to get a quick quote for your requirement.

We ensures that all 410 stainless steel panels are rigorously tested for quality, strength and durability. Each product is certified to appropriate industry standards, including mechanical components, corrosion resistance and finishes. These certifications assure reliable performance and compliance with global quality standards in industrial applications.

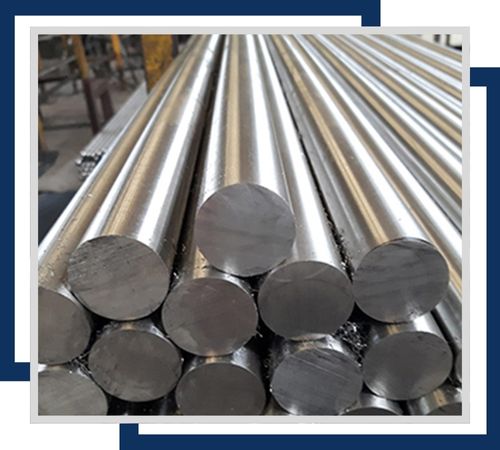

Corrosion-resistant and heat-treatable, Stainless Steel 410 Round Bars are available in diameters from 0.5″ to 12″. They are ideal for applications in cutlery, automotive parts, and industrial components requiring high hardness and moderate corrosion resistance.

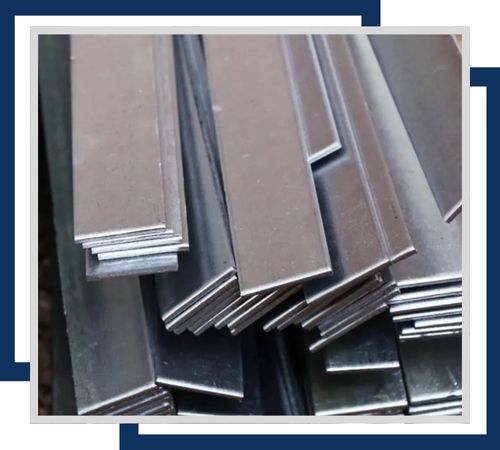

Stainless Steel 410 Flat Bars offer high strength and good machinability, with thicknesses from 0.25″ to 6″ and widths up to 12″. Suitable for manufacturing tools, hardware, and parts that need durability and wear resistance.

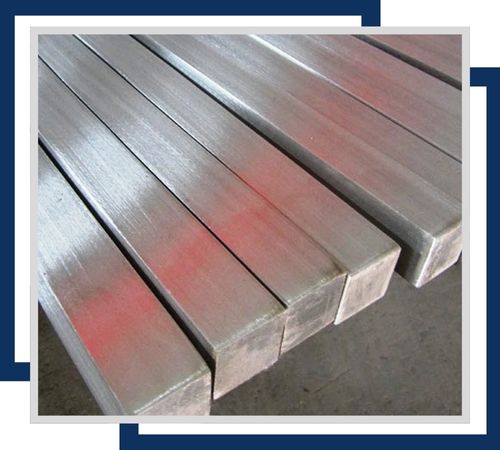

Corrosion-resistant Stainless Steel 410 Square Bars are available in sizes from 0.5″ to 6″ on each side. They are used in applications requiring high hardness and resistance to wear, such as in industrial machinery and components.

Stainless Steel 410 Rectangular Bars provide high strength and corrosion resistance, available in sizes from 0.5″ x 1″ to 6″ x 12″. Ideal for heavy-duty applications, including parts and tools that need excellent durability and wear resistance.

Offering good corrosion resistance and machinability, Stainless Steel 410 Hexagonal Bars come in sizes from 0.5″ to 4″ across flats. Suitable for use in hardware, machinery, and parts that require strength and durability.

Corrosion-resistant Stainless Steel 410 T-Bars are available in dimensions from 0.5″ x 0.5″ to 6″ x 6″. They are ideal for structural and industrial applications where high hardness and wear resistance are needed.

These bars are extensively used in industries that require materials that can withstand heat, resist corrosion, and provide mechanical strength. They’re perfect for applications like shafts, valve components, pump parts, precision machinery, and automotive assemblies. Additionally, they’re utilized in chemical processing, power generation, and industrial equipment that face high temperatures and moderately corrosive environments. The durability, wear resistance, and long service life of Stainless Steel 410 bars help minimize maintenance needs and ensure consistent performance, making them a smart choice for critical industrial and engineering applications.

©2024 Merih Stainless All Rights Reserved.