MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top manufacturer and supplier of Stainless Steel 439 pipes. They specialize in delivering high-quality solutions for industries that need heat resistance, corrosion protection, and long-lasting durability. Thanks to their cutting-edge manufacturing technology and strict quality control measures, every pipe produced meets international standards for mechanical performance, precision, and reliability. The Stainless Steel 439 pipes from MERIH STAINLESS are designed to thrive in demanding environments, boasting excellent dimensional stability, oxidation resistance, and scaling resistance. Available in a range of sizes and specifications, these pipes cater to the automotive, power generation, chemical, and industrial sectors around the globe.

Stainless Steel 439 pipes are made from ferritic stainless steel alloys, primarily consisting of iron and chromium, with small amounts of titanium and niobium added to enhance stability and corrosion resistance. With a chromium content of about 17–19%, these pipes excel in resisting high-temperature oxidation, scaling, and stress corrosion cracking. They also showcase impressive mechanical properties, including tensile strength, thermal stability, and dimensional reliability even at elevated temperatures. The ferritic structure provides magnetic properties and ensures consistent performance in tough industrial and engineering settings.

| Specifications | ASTM A/ASME SA268/A731 CL |

| Dimensions | ASTM, ASME and API |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Wall Thickness | Sch 5s, 10s, 40s, 80s, 160, XXS |

| Size – Seamless 439 Pipes | 1/2″NB – 24″NB |

| ERW 439 Pipes | 1/2″ NB – 24″ NB |

| EFW 439 Pipes | 6″ NB – 100″ NB |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| Types | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| End | Plain End, Beveled End, Treaded |

| Length | Single Random, Double Random & Cut Length. (Custom Sizes Available as per customers requirement) |

| Grade | C | Mn | Si | P | S | Cr | MO | Ni | CU | |

| 439 | Min | – | – | – | – | – | 12.0 | – | – | – |

| max | 0.15 | 1.00 | 1.00 | 0.04 | 0.03 | 14.0 | – | – | – | |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) | Brinell (HB) | ||||

| 439 | 95,000 | 50,000 | 25 | – | 175 |

Contact us to get a quick quote for your requirement.

We ensures the highest quality standards for Stainless Steel 439 Pipes through rigorous testing and certification processes. Every pipe goes through extensive tests, including chemical analysis, mechanical testing, and dimensional inspection. In this regard, we provide suitable certificates like Mill Test Certificate (MTC) and ISO certifications to make sure every product stands as a reliable brand and follows the market norms.

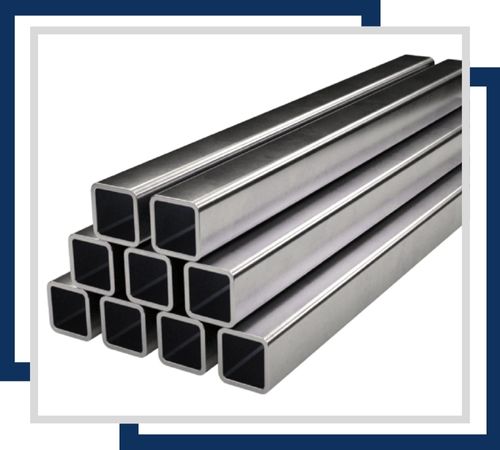

Stainless Steel 439 Square Pipes offer excellent corrosion resistance and are used in applications requiring a robust structure. They typically come in sizes ranging from 1/2″ to 8″, with wall thicknesses varying based on the application.

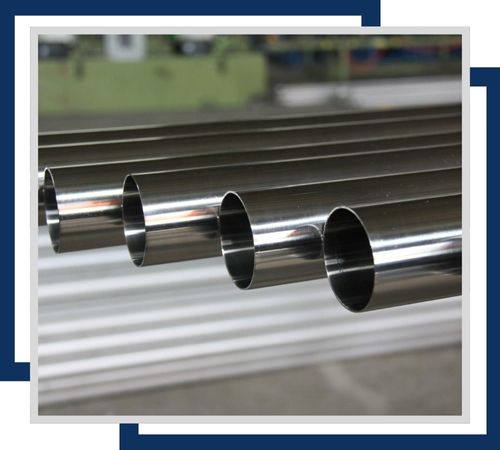

These pipes offer superior corrosion resistance and are used in high-temperature environments. They are available in sizes from 1/4″ to 12″ in diameter, with wall thicknesses ranging from 0.5mm to 20mm.

Providing good corrosion resistance, these pipes are manufactured using the electric resistance welding process. They are available in sizes from 1″ to 12″ in diameter, with various wall thicknesses for different pressure ratings.

These pipes, known for their corrosion resistance, are produced by longitudinal submerged arc welding. Sizes typically range from 6″ to 48″ in diameter, with wall thicknesses from 5mm to 25mm.

Offering excellent corrosion resistance, these pipes are used in various industries. They come in sizes from 1/4″ to 12″ in diameter, with wall thicknesses ranging from 1mm to 15mm.

These pipes exhibit good corrosion resistance and are made by welding flat plates. They are available from 1″ to 24″ in diameter, with wall thicknesses tailored to specific pressure and temperature requirements.

These Stainless Steel 439 pipes are widely utilized in industries that require both heat and corrosion resistance along with structural reliability. They are perfect for automotive exhaust systems, heat exchangers, furnace tubes, and boiler components. Moreover, they find applications in power plants, chemical processing facilities, and industrial machinery that face high temperatures and corrosive environments. Their durability, resistance to scaling, and ability to withstand thermal fatigue help minimize maintenance needs and guarantee long-term performance. Stainless Steel 439 pipes offer dependable, efficient, and safe solutions for critical applications in challenging industrial conditions.

©2024 Merih Stainless All Rights Reserved.