MERIH STAINLESS, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of Stainless Steel 446 bars, delivering high-quality solutions for industries that require durability and resistance to tough conditions. Thanks to cutting-edge production technology and rigorous quality checks, the company guarantees that each bar meets global standards for precision, strength, and performance. Known for their exceptional resistance to oxidation, scaling, and sulfidation at high temperatures, MERIH STAINLESS’s Stainless Steel 446 bars come in a range of sizes, shapes, and finishes, making them a trusted choice across various sectors and a dependable partner for industrial-grade stainless steel products.

These Stainless Steel 446 bars are made from ferritic stainless steel with a high chromium content, usually between 24–27%. This unique composition offers remarkable resistance to heat, scaling, and corrosion, even in harsh environments. They boast good tensile strength, hardness, and creep resistance, ensuring they perform reliably at elevated temperatures. Their ferritic structure gives them magnetic properties and enhances their stability under thermal stress. With excellent dimensional stability, toughness, and a long service life, these bars are perfect for applications that face corrosive gases and extreme heat.

Specification : EN, DIN, JIS, ASTM, BS, ASME, AISI

Standard Specification : ASTM A276, ASTM A479, ASTM A182

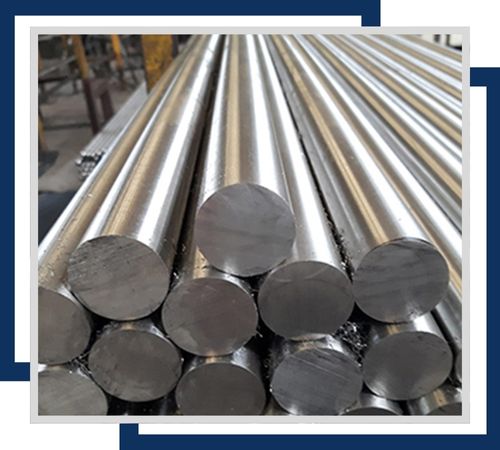

SS 446 Round Bars : Outside Diameter in the range of 4mm to 500mm

SS 446 Bright Bars : Outside Diameter in the range of 4mm to 200mm

SS 446 Hex Bars : 4mm – 101.6mm

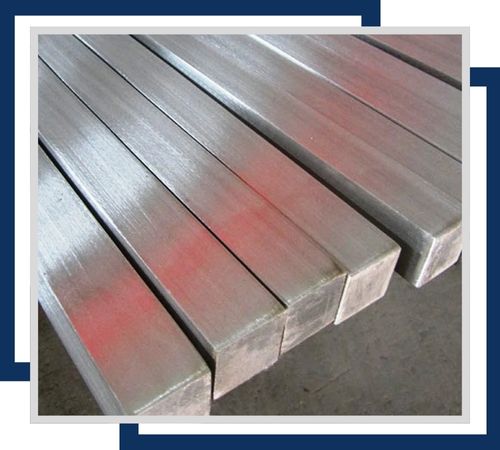

SS 446 Square Bars : 3mm – 100mm

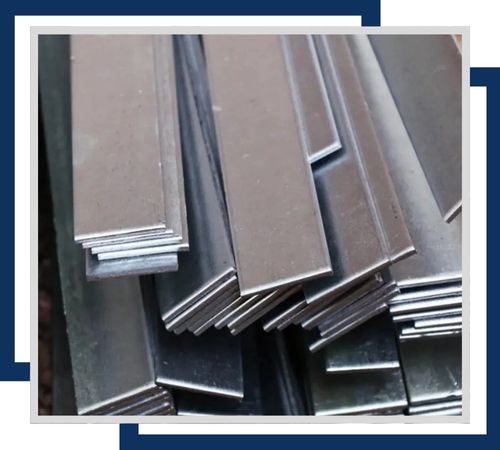

SS 446 Flat Bars : 1 / 2” to 10” in thickness range of 1.6mm to 150mm, Custom Size Stainless Steel Flats available

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Length : 1 to 6 Meters, Custom Cut Lengths

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Our SS 446 Round bars conforms to NACE MR0175/ISO 15156

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 446 | min. | – | – | – | – | – | 24.0 | – | – | 0.10 |

| max. | 0.2 | 1.5 | 0.75 | 0.040 | 0.030 | 26.0 | – | 0.50 | 0.25 | |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 446 | 485 | 275 | 20 | 92 | 201 |

Contact us to get a quick quote for your requirement.

We provides high-quality Stainless Steel 446 Bars for superior performance and durability. Every batch is tested rigorously, from mechanical to chemical and dimensional analysis, to meet international standards. We provide detailed certificates for every product, ensuring consistency, reliability, and compliance with industry specifications for your satisfaction and confidence.

Stainless Steel 446 Round Bars are designed for high-temperature applications, offering excellent resistance to oxidation and thermal degradation. Ideal for use in furnace parts, exhaust systems, and heat exchangers where durability and high performance under extreme conditions are required.

Stainless Steel 446 Flat Bars provide exceptional heat resistance and corrosion protection. They are used in manufacturing components for high-temperature environments, such as furnace linings, heat shields, and structural supports exposed to severe thermal conditions.

Stainless Steel 446 Square Bars are known for their high resistance to heat and oxidation. They are commonly utilized in high-temperature applications such as industrial furnaces, exhaust systems, and components that require robust performance under extreme heat and corrosive conditions.

Stainless Steel 446 Rectangular Bars offer outstanding heat and corrosion resistance, making them suitable for high-temperature environments. They are used in applications such as heat exchangers, furnace components, and structural elements where durability and performance are critical.

Stainless Steel 446 Hexagonal Bars provide superior resistance to high temperatures and oxidation. They are ideal for use in industrial settings requiring strong, heat-resistant components, such as in exhaust systems, furnace parts, and other high-temperature applications.

Stainless Steel 446 T-Bars are engineered for high-temperature and corrosive environments, offering excellent strength and thermal stability. Suitable for structural supports, heat exchangers, and furnace components, these bars ensure long-lasting performance in demanding conditions.

You’ll find Stainless Steel 446 bars widely used in industries that need top-notch heat and corrosion resistance. They’re perfect for furnace parts, boiler components, heat exchangers, and kiln equipment. Plus, they’re utilized in petrochemical plants, power generation facilities, and the cement and glass industries, where exposure to hot gases and scaling is a regular occurrence. Their ability to endure severe environments helps minimize downtime and maintenance costs while ensuring consistent performance. Stainless Steel 446 bars are the go-to choice for structural and engineering applications that require durability, efficiency, and stability in challenging operating conditions.

©2024 Merih Stainless All Rights Reserved.