MERIH STAINLESS, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of Stainless Steel 446 pipes, providing reliable solutions for industries that face tough operating conditions. With a solid reputation in stainless steel production, the company offers pipes that adhere to rigorous global standards for durability, corrosion resistance, and performance. Utilizing cutting-edge technology, MERIH STAINLESS ensures that their Stainless Steel 446 pipes are produced with precise dimensions, consistent quality, and a long lifespan. Their extensive range of sizes and specifications has made them a go-to partner for customers in need of trustworthy piping solutions for critical applications across various industrial sectors.

Stainless Steel 446 pipes are primarily made up of iron, chromium, and a few trace elements, classifying them as a ferritic stainless steel alloy. Thanks to their high chromium content, these pipes boast impressive resistance to oxidation, scaling, and sulfidation, even when exposed to high temperatures. They also showcase strong mechanical properties, including good tensile strength, hardness, and stability, while resisting creep and thermal fatigue. Their ferritic structure not only provides magnetic properties but also ensures dimensional stability under thermal stress, making Stainless Steel 446 pipes a great fit for demanding high-temperature environments.

| Specification : | ASTM F-899 / AMS 5936 |

| Standard : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

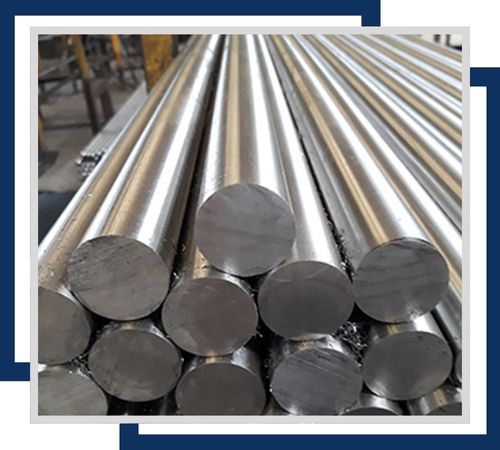

| Round Bars : | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars : | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars : | 18mm – 57mm (11/16″ to 2-3/4″) |

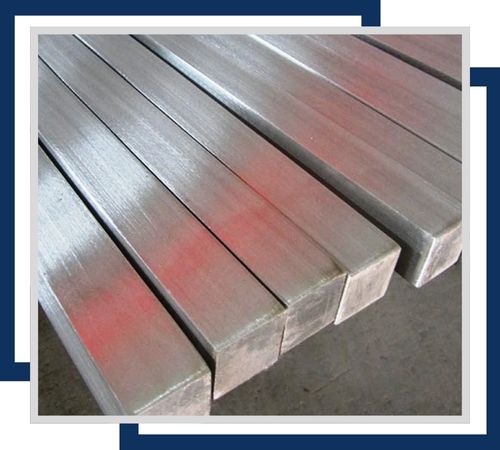

| Square Bars : | 18mm – 47mm (11/16″ to 1-3/4″) |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length : | 1 to 6 Meters, Custom Cut Lengths |

| Form : | Round, Square, Hex (A/F), Rectangle Etc. |

| Chemical Composition Limits | ||||||||||||

| Weight% | Mn | S | Cr | Mo | Ti | Fe | C | P | Si | Ni | Cu | Nb Ta |

| Alloy 465 | 0.50 max | 0.030 max | 11.00 – 12.50 | 0.50 max | 0.80 – 1.40 | Balance | 0.05 max | 0.040 max | 0.50 max | 7.50 – 9.50 | 1.50 – 2.50 | 0.10 – 0.50 |

| Material | Condition | Orientation | 0.2 % Yield Strength (Mpa) | Ultimate Tensile Strength (Mpa) | % Elongation in 4D | % Reduction of Area | Notch Tensile Strength | NTS/UTS | Charpy V Notch Impact | Rockwell C Hardness |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H950 | Long | 1655 | 1765 | 12 | 57 | 2475 | 1.40 | 16 | 49.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H950 | Trans | 1648 | 1765 | 11 | 49 | 2386 | 1.35 | 13 | 49.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H1000 | Long | 1496 | 1593 | 14 | 63 | 2427 | 1.52 | 35 | 47.5 |

| Alloy 465 Bar 3″ to 9″ Round Custom 465® | H1000 | Trans | 1503 | 1600 | 13 | 57 | 2392 | 1.50 | 28 | 47.5 |

Contact us to get a quick quote for your requirement.

We tests every bar of Stainless Steel 465 for quality, strength, and durability. All products are certified to international standards to give the customer a guarantee of performance and reliability. Every batch is tested for chemical composition, hardness, and corrosion resistance according to industry specifications.

SS 465 Bar Round Bar is a high-strength stainless steel alloy known for its excellent resistance to corrosion and wear. It is widely used in industries requiring robust performance, such as aerospace, chemical processing, and manufacturing. Available in various sizes, it offers durability and long-lasting functionality in harsh environments.

Stainless Steel 465 Flat Bar is a high-performance alloy known for its excellent resistance to corrosion, high temperature, and stress. It is commonly used in aerospace, automotive, and chemical industries due to its strength and durability. The flat bar form offers versatility for a range of structural and engineering applications.

SS 465 Square Bar is a high-strength stainless steel alloy with excellent corrosion resistance, especially in harsh environments. It is commonly used in industries like aerospace, automotive, and chemical processing. The square bar shape allows for easy machining and fabrication, providing versatility for structural and precision applications requiring durability.

Stainless Steel 465 Rectangular Bar is a high-performance alloy offering excellent corrosion resistance, strength, and durability, even in extreme conditions. It is widely used in aerospace, automotive, and chemical industries. The rectangular shape provides flexibility for various structural and engineering applications, ensuring reliability and long-lasting performance in demanding environments.

SS 465 Hexagonal Bar is a high-strength stainless steel alloy known for its excellent corrosion resistance and durability in harsh environments. It is commonly used in industries such as aerospace, automotive, and manufacturing. The hexagonal shape provides enhanced grip and unique design advantages, ideal for custom machining and structural applications.

SS 465 T-Bar is a high-strength stainless steel alloy known for its excellent corrosion resistance and durability. Commonly used in aerospace, automotive, and industrial applications, the T-bar shape provides structural stability and ease of installation. Its superior performance in extreme environments makes it ideal for demanding engineering and fabrication projects.

These pipes find extensive use in industries that require exceptional resistance to extreme heat and oxidation. They’re perfect for furnace components, heat exchangers, and boiler tubes, as well as in petrochemical plants and power generation facilities. Additionally, they are utilized in the cement, glass, and metallurgy sectors, where exposure to corrosive gases and high temperatures is a regular occurrence. Their ability to resist scaling and chemical attacks guarantees long-term reliability and minimizes maintenance needs. For applications that demand durability, heat resistance, and consistent performance in harsh operating conditions, Stainless Steel 446 pipes are the preferred choice.

©2024 Merih Stainless All Rights Reserved.