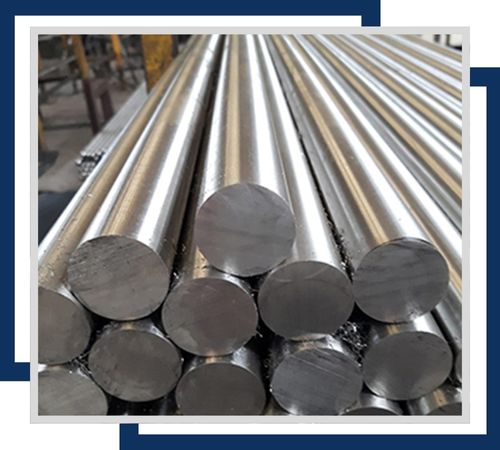

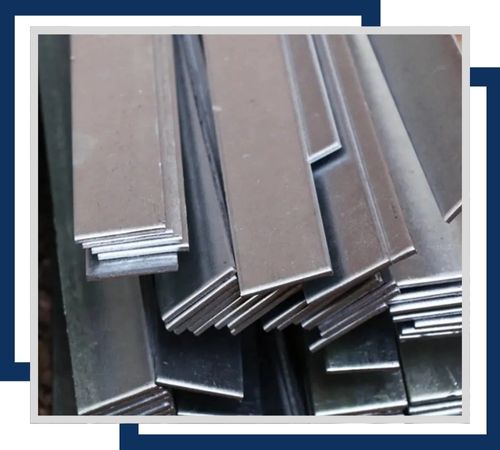

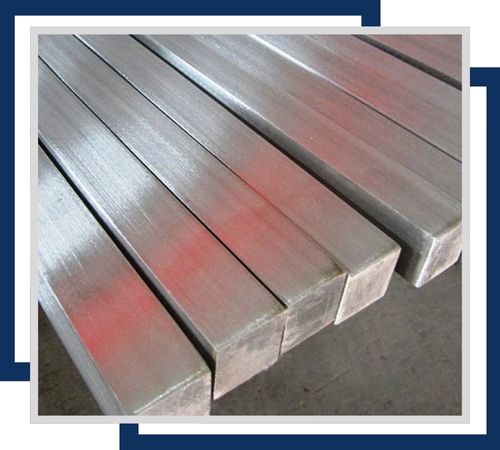

MERIH STAINLESS, located in Istanbul, Turkey, has earned a solid reputation as a reliable manufacturer and supplier of top-notch Stainless Steel Bars. They cater to industries around the globe with products that are both dependable and long-lasting. With a strong focus on precision engineering and using only the best raw materials, the company provides bars that adhere to international standards for strength, versatility, and performance. Their stainless steel bars come in a variety of grades, finishes, and sizes to meet the diverse needs of different industries. MERIH STAINLESS is dedicated to excellence, employing advanced manufacturing techniques, rigorous quality control, and solutions tailored to customer needs, making them a go-to partner for the construction, engineering, and manufacturing sectors worldwide.

Stainless Steel Bars are mainly made up of iron, chromium, and nickel, with other elements like molybdenum, manganese, and carbon added to boost performance. The chromium gives these bars outstanding resistance to corrosion, while nickel enhances their toughness and durability. They showcase impressive mechanical properties, such as high tensile strength, heat resistance, and superior hardness. Their well-balanced composition guarantees precise dimensions, wear resistance, and long-lasting performance even in tough conditions. Thanks to their excellent machinability, weldability, and formability, stainless steel bars are perfect for critical applications across a range of industries.

| Stainless Steel Bar Length | 2 to 6 meters or 8 to 20 feet |

|---|---|

| SS Rod Chamfering | Available in 30, 45 & 60 degree thru fully automatic both-end chamfering machine |

| Ultrasonic Test of ASTM A276 Threaded Rod | As per ASTM A-388, EN 10308 (class 1 to 4), API 6A/ISO it is 100% tested thru Digital Ultrasonic Flaw Detector, 10423:2003-PSL 3, MIL STD 2154, SEP 1920:1984 |

| SS Round Bar Size Tolerances | h11 |

| Tolerance of Cold Rolled SS Round Bar Length | Stock in special cut to length bar in tolerance – 0/+10mm (-0 +0.5 inch) |

| Surface Finish of Cold Rolled SS Bar | Cold drawn or Belt polished condition |

| Bar Heat Treatment | Annealed and Solution Annealed |

| Element | Stainless Steel Bars |

| Ni | 8.0 – 10.5 |

| C | 0.08 |

| Mn | 2.0 max |

| P | 0.045 max |

| S | 0.030 max |

| Si | 0.75 max |

| Cr | 15.0 – 18.0 |

| Mo | – |

| N | 0.10 |

| Element | SS Bars |

| Tensile Strength (MPa) min | 515 |

| Yield Strength 0.2% Proof (MPa) min | 205 |

| Elongation (% in 50mm) min | 40 |

| Rockwell B (HR B) max Hardness | 92 |

| Brinell (HB) max Hardness | 201 |

Contact us to get a quick quote for your requirement.

We ensure the full transparency of our Stainless Steel Bars with high-quality assurance. All orders have essential documents in the form of a commercial invoice, packing list, fumigation certificate, heat treatment chart, and a NABL-approved lab test report. We offer Material Test Certificate per EN 10204/3.1b, PMI Test Certificate, 100% radiography test report, and Third-Party Inspection Certificate. Our total documentation is arranged to ensure maximum client satisfaction.

Yes, Stainless Steel Bars are highly corrosion-resistant due to the presence of chromium, which forms a protective oxide layer. This makes them ideal for use in harsh environments.

The pressure rating of stainless steel bars depends on factors such as grade, size, and application. Typically, they are designed to withstand high pressures, ranging from 150 to 1,000 PSI, depending on specifications.

Yes, stainless steel bars can be ordered in custom sizes and polishes to meet specific requirements. Many suppliers offer customization options for dimensions, finishes, and surface treatments. For more details mail us on sales@merihstainless.com

These Stainless Steel Bars are popular in various sectors because of their strength, reliability, and corrosion resistance. In construction, they play a crucial role in structural frameworks, reinforcement, and architectural features. The automotive and aerospace industries utilize them for shafts, fasteners, and precision components. In manufacturing, they are essential for machinery, tools, and equipment that require high durability. The marine industry depends on them for shipbuilding and offshore projects due to their resistance to corrosion. Moreover, stainless steel bars are indispensable in chemical processing, food production, and energy sectors, ensuring safety and efficiency in demanding environments.

©2024 Merih Stainless All Rights Reserved.