Home > Electrodes > Stainless Steel Electrodes

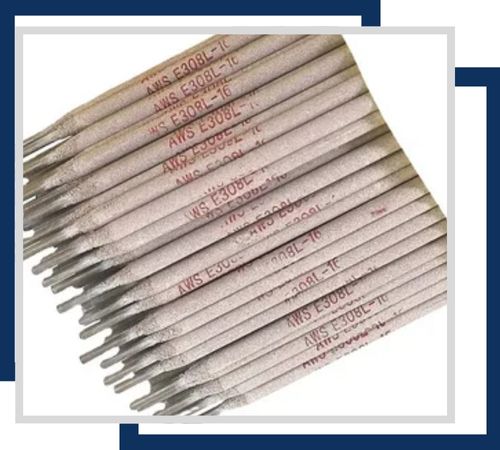

MERIH STAINLESS, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of premium Stainless Steel Electrodes. Crafted for precision, reliability, and resistance to corrosion, these electrodes ensure consistent performance in welding and metal fabrication tasks. MERIH STAINLESS is committed to meeting international standards for mechanical strength, chemical makeup, and operational efficiency with every electrode. They find applications across various industries, including petrochemical, chemical, food processing, marine, and construction, delivering robust, durable welds, excellent arc stability, and a long service life. They’re perfect for joining stainless steel parts in high-pressure, high-temperature, and corrosive settings.

The Stainless Steel Electrodes from MERIH STAINLESS are made from high-quality stainless steel alloys that include iron, chromium, nickel, and trace elements, ensuring they resist corrosion while maintaining toughness and weld integrity. Their mechanical properties feature high tensile strength, optimal ductility, and hardness that are perfect for heavy-duty welding tasks. These electrodes provide outstanding arc stability, smooth welding performance, and resistance to oxidation and contamination. With precision manufacturing, they guarantee a consistent chemical composition and reliable fusion, making them ideal for creating strong, corrosion-resistant, and long-lasting joints in challenging industrial and fabrication environments.

| Specifications | AWS A5.14 ERNiCr-3, AWS A5.11 ENiCrFe-3 |

| International Specifications | BS 3072-3076 (NA14) DIN 17742, DIN 17750, DIN 17754 WERKSTOFF Nr 1.4301 TÜV 305 AFNOR-NC 15 Fe |

| Size | 2.00 mm Dia., 2.50 mm Dia., 3.15 mm Dia., 4 mm Dia., 5 mm Dia., 6.3 mm Dia. |

| Length | 300 mm to 450 mm |

| Model | Chemical Composition | |||||||||

| C | Mn | Si | S | P | Cr | Ni | Mo | Cu | Nb | |

| AWS E308-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.75 | — |

| AWS E308L-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.75 | — |

| AWS E309-16 | 0.15 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.75 | — |

| AWS E309L-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 22.0-25.0 | 12.0-14.0 | 0.75 | 0.75 | — |

| AWS E309MoL-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 22.0-25.0 | 12.0-14.0 | 2.0-3.0 | 0.75 | — |

| AWS E310-16 | 0.08-0.20 | 1.0-2.5 | 0.75 | 0.03 | 0.03 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.75 | — |

| AWS E312-16 | 0.15 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 28.0-32.0 | 8.0-10.5 | 0.75 | 0.75 | — |

| AWS E316-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 17.0-20.0 | 11.0-14.0 | 2.0-3.0 | 0.75 | — |

| AWS E316L-16 | 0.04 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 17.0-20.0 | 11.0-14.0 | 2.0-3.1 | 0.75 | — |

| AWS E318-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 17.0-20.0 | 11.0-14.0 | 2.0-3.2 | 0.75 | 6xC-1.00 |

| AWS E347-16 | 0.08 | 0.5-2.5 | 0.9 | 0.03 | 0.04 | 18.0-21.0 | 9.0-11.0 | 0.75 | 0.75 | 8xC-1.00 |

| AWS E410-16 | 0.12 | 1 | 0.9 | 0.03 | 0.04 | 11.0-13.5 | 0.7 | 0.75 | 0.75 | — |

| Model | Machanical Properties of Deposited Metal | |||

| Tensile Strength | Elongation | |||

| (Mpa) | (%) | |||

| AWS E308-16 | >550 | >35 | ||

| AWS E308L-16 | >520 | >35 | ||

| AWS E309-16 | >550 | 25 | ||

| AWS E309L-16 | >550 | >25 | ||

| AWS E309MoL-16 | >540 | >25 | ||

| AWS E310-16 | >550 | >25 | ||

| AWS E312-16 | >660 | >22 | ||

| AWS E316-16 | >520 | >30 | ||

| AWS E316L-16 | >490 | >30 | ||

| AWS E318-16 | >550 | >25 | ||

| AWS E347-16 | >550 | >25 | ||

| AWS E410-16 | >450 | >20 | ||

Contact us to get a quick quote for your requirement.

Designed for excellent corrosion resistance, these electrodes are ideal for thin stainless steel sections and are typically available in sizes like 1.6mm to 4.0mm in diameter. Their light coating provides good penetration and easy handling.

These electrodes offer superior corrosion resistance and are used for thicker stainless steel sections. They come in larger sizes, ranging from 3.2mm to 5.0mm in diameter, and their heavy coating ensures enhanced arc stability and better fill rates.

Providing outstanding corrosion resistance, these electrodes are used in shielded metal arc welding. They are available in various sizes, including 2.0mm to 4.0mm, and are known for their high-quality welds and resistance to high-temperature environments.

Merih Stainless offers top-notch quality material material that goes through rigid test procedure to ascertain maximum performance. We perform our materials with hardness test, spectrochemical analysis, PMI testing, micro and macro testing, flaring, pitting resistance, and IGC tests to make sure our materials achieve the highest standards. Along with this commitment to excellence, we also provide our clients with all the documentation necessary, like commercial invoices, packaging lists having precise net and gross weights, box numbers, and labels. A legalized or attested Certificate of Origin along with a Third-Party Inspection Certificate ensures 100% transparency and client satisfaction in our stainless steel electrodes pricing.

Choose stainless steel electrodes based on the base material’s grade, application (corrosion, heat, or strength requirements), and welding position. Ensure compatibility with the operating environment and desired mechanical properties.

Yes, you can order Stainless Steel Electrodes in custom sizes and polishes to meet your specific requirements. For more details, mail us at sales@merihstainless.com

Stainless steel electrodes typically do not require additional corrosion protection coatings because they inherently resist corrosion due to their chromium content. However, coatings may be applied in extreme environments for added protection.

Yes, stainless steel electrodes can be used in cryogenic applications due to their excellent toughness and strength at low temperatures, along with superior corrosion resistance. They are ideal for welding materials exposed to cryogenic environments.

Stainless Steel Electrodes are extensively utilized for welding stainless steel components in various industrial, commercial, and construction settings. They are commonly found in chemical and petrochemical plants, oil and gas pipelines, marine and offshore structures, food and beverage processing equipment, power generation systems, and structural fabrication. These electrodes ensure strong, durable, and corrosion-resistant welds, which contribute to the safety, efficiency, and longevity of welded structures.

©2024 Merih Stainless All Rights Reserved.