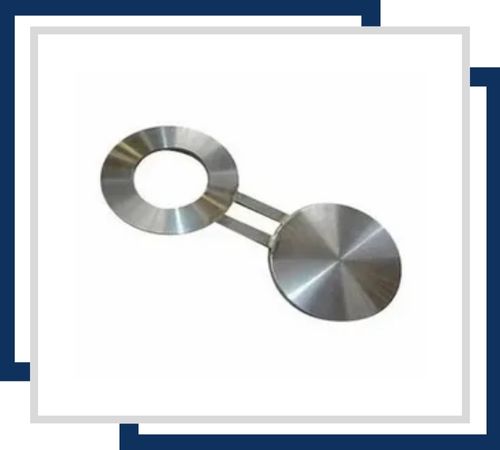

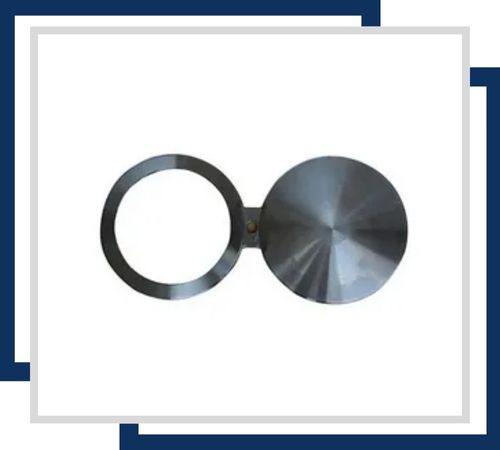

MERIH STAINLESS, located in Istanbul, Turkey, stands out as a top-notch manufacturer and supplier of premium stainless steel products, with a special focus on Stainless Steel Spectacle Blind Flanges. Known for their precision engineering and durability, MERIH STAINLESS serves a variety of industrial sectors, offering flanges that adhere to international standards. Their dedication to excellence guarantees reliable performance, resistance to corrosion, and a long lifespan. With cutting-edge manufacturing facilities and a passionate team, MERIH STAINLESS provides tailored solutions to meet the unique needs of their clients, making them a go-to partner for industries in search of sturdy and trustworthy stainless steel flange options.

Stainless Steel Spectacle Blind Flanges are generally made from high-quality stainless steel, including grades 304, 304L, 316, and 316L, which provide outstanding corrosion resistance and mechanical strength. These flanges are designed to withstand high tensile strength, endure pressure, and resist oxidation and chemical exposure. Engineered with precision to maintain tight tolerances, they ensure reliable sealing capabilities. Their robustness guarantees performance even in extreme temperatures and high-stress situations, making them perfect for critical industrial applications where structural integrity and safety are crucial, such as in the chemical, petrochemical, and power generation sectors.

| Size | 1/2″ to 48″ |

| Standards | MSS SP44, ASA, ANSI B16.47 Series A & B, ANSI B16.5, API-605, AWWA, Custom Drawings. |

| Pressure Ratings | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Pressure class | 150#, 300#, 600#, 1500# |

| Dimensions | BS3293, Table D, E, F, & H, ANSI, PN6, 10, 16, 25, 64 BS10, BS4504, MSS- SP-44, DIN Standards |

| Flange Face Type Manufacturer | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Coating/Surface Treatment | Oil Black Paint, Yellow Transparent, Anti-rust Paint, Zinc Plated, Cold and Hot Dip Galvanized. |

| Test | Hydrostatic testing machine, X-ray detector, Direct-reading Spectrograph, UI trasonic flaw detector, Magnetic particle detector |

|---|

Contact us to get a quick quote for your requirement.

We ensure complete transparency for our Stainless Steel Spectacle Blind Flanges with top-quality assurance. Every order is accompanied by essential documentation, including a commercial invoice, packing list, fumigation certificate, heat treatment chart, and a NABL-approved lab test report. We provide Material Test Certificates as per EN 10204/3.1b, PMI Test Certificates, 100% radiography test reports, and Third-Party Inspection Certificates. Our comprehensive documentation is meticulously organized to guarantee maximum client satisfaction.

When selecting a stainless steel spectacle blind flange, consider factors such as pressure rating, temperature resistance, corrosion resistance, and compatibility with the system’s fluid and mechanical conditions. Additionally, ensure the flange material aligns with the specific environmental and industrial requirements.

Yes, you can order Stainless Steel Spectacle Blind Flange in custom sizes and polishes to meet your specific requirements. For more details, mail us at sales@merihstainless.com

Stainless Steel Spectacle Blind Flanges typically do not require corrosion protection coatings due to their inherent corrosion resistance. However, in highly corrosive environments, additional coatings may be applied for enhanced protection.

Stainless Steel Spectacle Blind Flanges are mainly used to isolate sections of pipelines for maintenance, inspection, or safety reasons. They act as either a temporary or permanent barrier, allowing operators to stop the flow without needing to disassemble the pipeline. Commonly utilized in the oil and gas, chemical, petrochemical, and water treatment industries, they help prevent leaks, ensure operational safety, and make system shutdowns easier. Plus, their corrosion resistance and durability make them well-suited for high-pressure and high-temperature environments, supporting the longevity of piping systems while ensuring compliance with industry standards.

©2024 Merih Stainless All Rights Reserved.